As such it is a complex design which needs experience of Process Microbiology the engineering. Contact your Sartorius representative and configure your Biostat B. bio fermenter design.

Bio Fermenter Design, Stirrer glands and bearings. It is highly challenging in the case of pilot-scale fermenters. Vasanth Raj Raghu.

Fermentation Bioprocessing From bioprocessing.weebly.com

Fermentation Bioprocessing From bioprocessing.weebly.com

After this process if you add some. Fermentors are extensively used for food processing fermentation waste treatment etc. Stirrer glands and bearings.

An Overview of Fermenter and the Design Considerations to Enhance Its Productivity Hitesh Jagani Karteek Hebbar Sagar S.

Bio-fermentation is a method of processing organic material to produce raw material or products. A Groups of Biogas microbes - B Groups of microbes involved in the 3 stages of biogas fermentation - 1st stage. This vessel is utilized to support the growth conditions of microorganisms carrying out fermentation. History of Fermentors 3. Our Fermenter designs for both mammalian and prokaryotic systems range from a working volume of 10 to 100000 Liters. Its design and construction must provide the optimum environment conditions to the microorganisms.

Another Article :

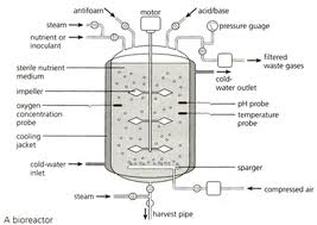

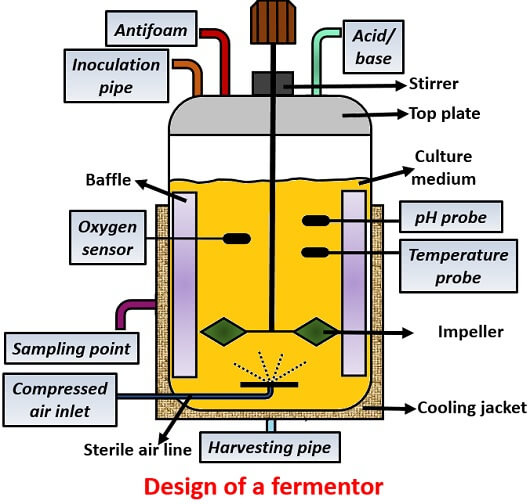

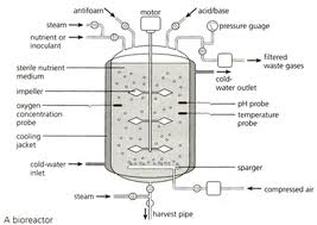

A fermentor is used for commercial production in fermentation industries and is a device in which a substrate of low value is utilized by living cells or enzymes to generate a product of higher value. Its design and construction must provide the optimum environment conditions to the microorganisms. This vessel is utilized to support the growth conditions of microorganisms carrying out fermentation. Basic component includes drive motor heaters pump etc. A fermentor is used for commercial production in fermentation industries and is a device in which a substrate of low value is utilized by living cells or enzymes to generate a product of higher value. Design Of Fermenter Microbiology With Sumi Youtube.

Bio-fermentation is a method of processing organic material to produce raw material or products. Special mixers available like anchor. Compatibility with up- downstream processes. Shree Biocare Solution Pvt Ltd. An Overview of Fermenter and the Design Considerations to Enhance Its Productivity Hitesh Jagani Karteek Hebbar Sagar S. Gcse Biology Fermenters.

A fermentor should provide the facility to control and monitor various parameters for a successful fermentation process. Vasanth Raj Raghu. 12 Mechanism of biogas fermentation. Shree Biocare Solution Pvt Ltd. History of Fermentors 3. .

Meaning of Fermentor 2. These stirrer shafts play an. The concentrations of. Fermenter Design 31 Components of a fermenter. Fermenter for biofertilizer production is the most efficient machine among all the industrial composting equipment. Industrial Fermentation Basic Design Media Preparation Production.

03 to 04 of tank diameter Agitation speed. Biogas can be obtained from any organic materials after anaerobic fermentation by three main phases. This vessel is utilized to support the growth conditions of microorganisms carrying out fermentation. Shree Biocare since company inception in 2004We are engaged in designing manufacturing research training trouble shooting in Fermentation and Bioreactor equipment and plantSB focused towards customer satisfaction SB adopted a customer-oriented approach and Serving clients all across globe SB developed a complete understanding clients requirements and. Bio fuel cells and gas phase bioreactors. Fermenters Bioninja.

Stainless steel Height to diameter ratio of the vessel. Design will be in stainless steel. As such it is a complex design which needs experience of Process Microbiology the engineering. Stainless steel Height to diameter ratio of the vessel. The concentrations of. Design Of A Fermentor Industrial Microbiology General Microscience.

Contact your Sartorius representative and configure your Biostat B. Fermenter Design 31 Components of a fermenter. Bioreactors are commonly cylindrical vessels with. DESIGN OF BIOGAS PLANT Bio-gas Project LGED 11 Introduction. In a stainless steel organic waste bio-reactor harmful bacteria insect eggs and grass seeds will be inactivated under the temperature of 80-100. Fermenter Designing Youtube.

Fermentor Bioreactor A bioreactor is a specially designed vessel which is built to support the growth of high concentration of microorganisms. Stirrer glands and bearings. In any biological process the following are unique features. A fermentor bioreactor is a closed vessel with adequate arrangement for aeration agitation temperature and pH control and drain or overflow vent to remove. It is a kind of non-polluted machinery. Bioreactor Definition Design Principle Parts Types Applications Limitations.

In fermenters are biological reactions are allowed to occur under very controlled conditions Bhagry et al 2008. Stirrer glands and bearings. Most of the FBBs developed for biological systems involving cells as biocatalysts are three phase systems. Fermentor Bioreactor A bioreactor is a specially designed vessel which is built to support the growth of high concentration of microorganisms. The concentrations of. Characteristics Of Ideal Fermenter Biology Ease.

Fermentors are extensively used for food processing fermentation waste treatment etc. Therefore stirrer shafts are required. It is highly challenging in the case of pilot-scale fermenters. After this process if you add some. Our Fermenter designs for both mammalian and prokaryotic systems range from a working volume of 10 to 100000 Liters. Criteria For Fermentor Designing Biology Ease.

Basic component includes drive motor heaters pump etc. For any bio-pharma processes after fermentation batch in fermenter Bioreactor there are multiple unit operations of cell harvest. Shree Biocare Solution Pvt Ltd. An Overview of Fermenter and the Design Considerations to Enhance Its Productivity Hitesh Jagani Karteek Hebbar Sagar S. Contact your Sartorius representative and configure your Biostat B. Fermentation Tank Fluid Process Pro.

A fermentor should provide the facility to control and monitor various parameters for a successful fermentation process. As such bioreactor systems must be designed to provide a higher degree of. Contact your Sartorius representative and configure your Biostat B. Cooling-coil length in fermenter design. It must be so designed that it is able to provide the optimum environments or conditions that will allow supporting the growth of the microorganisms. Fermentation Bioprocessing.

Fermentor is a kind of culture vessel in which the raw materials and microorganisms perform chemical and biological activity to produce biologically important products like enzymes. 2 to 1 or 3 to 1 Impeller Two or three disk turbine impellers Diameter. Fermentor is a kind of culture vessel in which the raw materials and microorganisms perform chemical and biological activity to produce biologically important products like enzymes. Microbial fermentations received prominence during 1940s namely for the production of life saving antibiotics. These reactors are simple in design and easier to operate. Design Of The 5 L Working Volume Anaerobic Bioreactor Used In This Download Scientific Diagram.

03 to 04 of tank diameter Agitation speed. Cooling-coil length in fermenter design. As such bioreactor systems must be designed to provide a higher degree of. A fermentor is used for commercial production in fermentation industries and is a device in which a substrate of low value is utilized by living cells or enzymes to generate a product of higher value. Its design and construction must provide the optimum environment conditions to the microorganisms. Fermentation Chamber Fermentor Bioreactor China Manufacturer China Fermentation Tank Fermentor Fermentation Pilot Plant Made In China Com.

Bio-fermentation is a method of processing organic material to produce raw material or products. A fermentor is used for commercial production in fermentation industries and is a device in which a substrate of low value is utilized by living cells or enzymes to generate a product of higher value. Contact your Sartorius representative and configure your Biostat B. Vasanth Raj Raghu. 50 200 rpm Impeller - shaft enters either from the top or bottom. Design And Operation Of The Fermenter Fermentation Vessel Microbiology Class.