Our mechanical and structural engineers have decades of experience in the design and manufacture of custom belt feeders and hoppers to suit a wide range of materials and feed rates. Because mining processes vary with companies the. belt feeder design.

Belt Feeder Design, Feeders onto conveyor belts. The basic design features of belt and apron feeders is presented. A belt feeder can be used to transport and meter.

Conveyor Belt 3d Model Ad Conveyor Belt Model Conveyor Belt Conveyor Belt From ar.pinterest.com

Conveyor Belt 3d Model Ad Conveyor Belt Model Conveyor Belt Conveyor Belt From ar.pinterest.com

Head load is the single most important factor in belt feeder design. The belt feeder discharge is positive volumetric in nature. Belt feeder design come in a very diverse selection that holds distinct sizes shapes and models to ensure all shoppers.

Therefore the design of the hopper and the belt feeder and the loads on the belt are very much dependent and connected.

Bulk solids handling - Vol. Starting Load Calculations AE. The need for feeders and mass-flow hoppers to be designed as an integral unit to promote uniform feed is emphasised. This conveyor is around 600 metres long with a vertical lift of around 70 metres and transfers 15 MTPA. If the job will stand the additional cost some type of mechanical feeding device may be employed such as a belt feeder apron feeder pan feeder. Several factors influence belt feeder operation and reliability.

Another Article :

Belt feeders need a good design what bringing easy operation and maintenance. Keep belt clean from food build up and kept as dry as possible. As an example a mine in Germany has 6400 mm wide belt feeder for handling lignite at much higher capacity. Metso Outotecs belt feeders offering consists of standard capacity BF Series belt feeders and higher capacity models known as BFH belt feeders. The book provides interesting and useful information about the pressure calculation from hopper however the presented information is in context of belt feeder. Pin On Diy Conveyor.

Belt feeders are commonly used when material that is either stockpiled or loaded at an uncontrolled rate in a bin or hopper needs to be introduced into the system at a controlled feed rate. They are preferable when handling friable coarse fibrous elastic sticky or. The importance of correct chute design to ensure efficient transfer of bulk solids without spillage and. Belt feeder design considerations. The belt feeder design cannot be done unless the pressure values at interface are known. 254 Conveyor Belt Feeder Hopper Free Download 3d Model Conveyor 3d Model Conveyor Belt.

Head load is the single most important factor in belt feeder design. Belt feeder design considerations. Bulk solids handling - Volumes. Therefore the design of the hopper and the belt feeder and the loads on the belt are very much dependent and connected. The Black Star open pit mine at Mt Isa in northern Queensland is an important part of Glencore Xstratas Mount Isa Mines mining operations. Heavy Duty Dj Series Inclined Corrugated Sidewall Belt Conveyor For Mining Is For Transferring Nut Material To Related Equipment Conveyor Conveyors Corrugated.

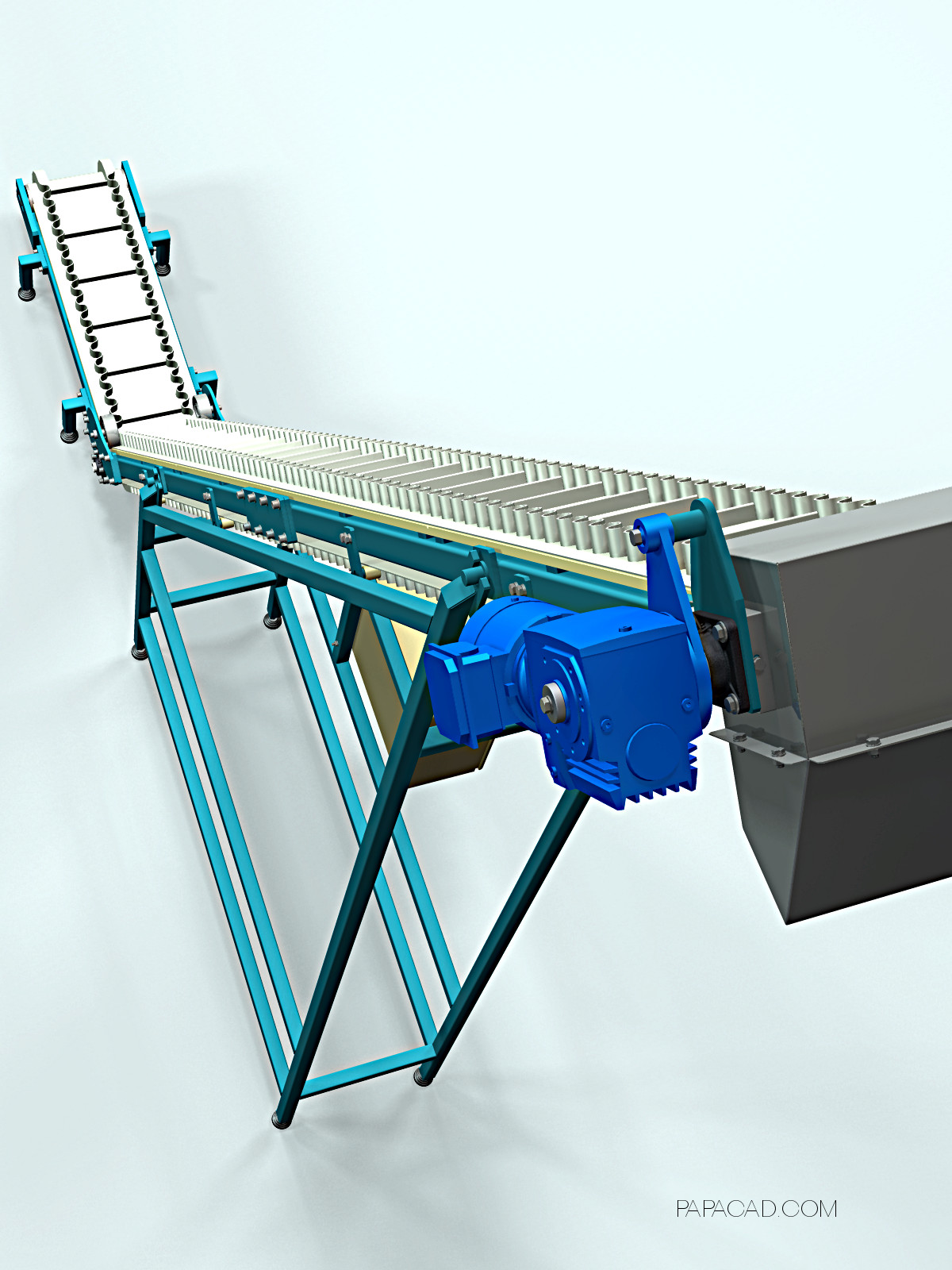

The main components of the belt feeder are identified in the Figure 9. Finally specify final design details and additional construction elements for the construction of belts and sprockets to the system. As an example a mine in Germany has 6400 mm wide belt feeder for handling lignite at much higher capacity. The space-saving design also saves on investment costs. To solve a conveyor problem certain facts must first be known. The Frame Of The Portable Belt Conveyor Conveyor Henan Conveyors.

Examples include when the feed rate uniformity must be better than 2 or sample collection times must be less than about 30 sec. The typical capacity range is up to 1500 m3hour for regularly used belt widths. Bulk solids handling - Vol. Gravimetric feeders are loss-in-weight and weigh belt. Bulk solids handling - Volumes. Vibratory Feeder And Portable Belt Conveyor Ordered By Kazakhstan And Philippines Clients Have Been Delivered Conveyor Conveyors Portable.

How it works Simply open the cover pull back the belt place feed on belt and close the cover and feed will drop out below over a 12 or 24 hour period. Belt conveyors are suitable for the conveying of a large range of products - from powders to large bulk solids. Figure 9 Main components of the belt feeder. Comprised of a conveyor belt on rollers. However belt feeders of higher capacities are also possible. 3d Design Of Four Section Telescopic Belt Loading Conveyor Conveyor Mechanical Design Telescope.

Belt feeders are commonly used when material that is either stockpiled or loaded at an uncontrolled rate in a bin or hopper needs to be introduced into the system at a controlled feed rate. Feeders onto conveyor belts. Head load is the single most important factor in belt feeder design. However belt feeders of higher capacities are also possible. Examples include when the feed rate uniformity must be better than 2 or sample collection times must be less than about 30 sec. Portable Belt Conveyor Conveyor System Conveyor Conveyors.

Belt feeder design possess cutting-edge inventions in their designs that make feeding mining ores and other products to the mining mill straightforward. Belt feeders are often an excellent choice when feeding material from an elongated hopper outlet but can also be used with square or round outlets. The importance of correct chute design to ensure efficient transfer of bulk solids without spillage and. Figure 9 Main components of the belt feeder. Gravimetric feeders should be used whenever there is a requirement for close control of material discharge. Pin On Conveyor Belt.

The need for feeders and mass-flow hoppers to be designed as an integral unit to promote uniform feed is emphasised. Bulk solids handling - Volumes. Keep belt clean from food build up and kept as dry as possible. Factors to Consider in Belt Feeder Design. The essential requirement is to promote uniform feed with. Incline Feeder Machine Acclivitous Conveyor Conveyor System Conveyor Packaging Machine.

Keep belt clean from food build up and kept as dry as possible. Belt feeder design considerations. The book provides interesting and useful information about the pressure calculation from hopper however the presented information is in context of belt feeder. The need for feeders and mass-flow hoppers to be designed as an integral unit to promote uniform feed is emphasised. If the job will stand the additional cost some type of mechanical feeding device may be employed such as a belt feeder apron feeder pan feeder. Pin On Diy Conveyor.

Therefore substantial portion of this book is devoted to pressure values from hopper. The belt feeder design cannot be done unless the pressure values at interface are known. This conveyor is around 600 metres long with a vertical lift of around 70 metres and transfers 15 MTPA. Several factors influence belt feeder operation and reliability. Design and application of feeders for the controlled loading of bulk solids onto conveyor belts. Pin On Diy Conveyor.

Start up automatic feed supply with the Belt Feeder. Belt feeders can be applied to withdraw fines or wet materials under hoppers bins or stock piles to provide the desired continuous feed rate for screens crushers and conveyors. The main components of the belt feeder are identified in the Figure 9. The belt feeder discharge is positive volumetric in nature. The essential requirement is to promote uniform feed with. If You Operate Like This The Screw Conveyor Will Become A Pile Of Scrap Metal Soon Conveyors Conveyor Recycling Machines.

Finally specify final design details and additional construction elements for the construction of belts and sprockets to the system. BHT Belt Feeders are designed and manufactured to ensure long life and reliable service in the harshest of operating environments. The interface design relies on a variable speed belt to achieve a variable product flow rate. Belt feeders are often an excellent choice when feeding material from an elongated hopper outlet but can also be used with square or round outlets. Gravimetric feeders should be used whenever there is a requirement for close control of material discharge. Chore Time S 20 Hole Side Belt Nest Boxes Are Designed For Continuous Use With Very Little Maintenance The Eggs Ro Poultry Supplies Poultry House Poultry Farm.

The essential requirement is to promote uniform feed with. Several factors influence belt feeder operation and reliability. They are preferable when handling friable coarse fibrous elastic sticky or. Our mechanical and structural engineers have decades of experience in the design and manufacture of custom belt feeders and hoppers to suit a wide range of materials and feed rates. Basic Objectives for Uniform Draw-Down An overview design and performance focussing on of feeder belt and apron feeders is presented The importance of correct For unrform draw-down with a fully active hopper outlet the ca- hopper and feeder interfacing is stressed The objective is to pacity of the feeder must progressively increase in the direction achieve uniform draw-down. Feed Discharge Conveyor For Parts Conveyor Conveyors Conveyor System.

Basic Objectives for Uniform Draw-Down An overview design and performance focussing on of feeder belt and apron feeders is presented The importance of correct For unrform draw-down with a fully active hopper outlet the ca- hopper and feeder interfacing is stressed The objective is to pacity of the feeder must progressively increase in the direction achieve uniform draw-down. Bulk solids handling - Volumes. Belt feeder design come in a very diverse selection that holds distinct sizes shapes and models to ensure all shoppers. This Custom Conveyor System was designed for a manufacturer who needed to load empty trays with parts for an automatic assembly operation. Because mining processes vary with companies the. Pin By Savona Equipment On Feeders Hoppers Conveyors Gate Conveyor.