What are the Advantages of Axial Flux Motor. The axial engine architecture allows us to implement our constant volume combustion cycle delivers extremely low vibration in a convenient quasi-cylindrical package and we have overcome the traditional limitations associated with the configuration. axial engine design.

Axial Engine Design, In the axial flux design the magnets and stator are arranged with the poles parallel to the shafting and the flux directed axially hence the name. That opens up new design options within the vehicle platform such as where to place the battery packs. ARRAY ELECTRIC MOTOR model which is an axial flux electric motor with axis orientation perpendicular to the ground as shown in Figure 13 which in some cases simplifies mechanical assembly o change the direction of application of the torque.

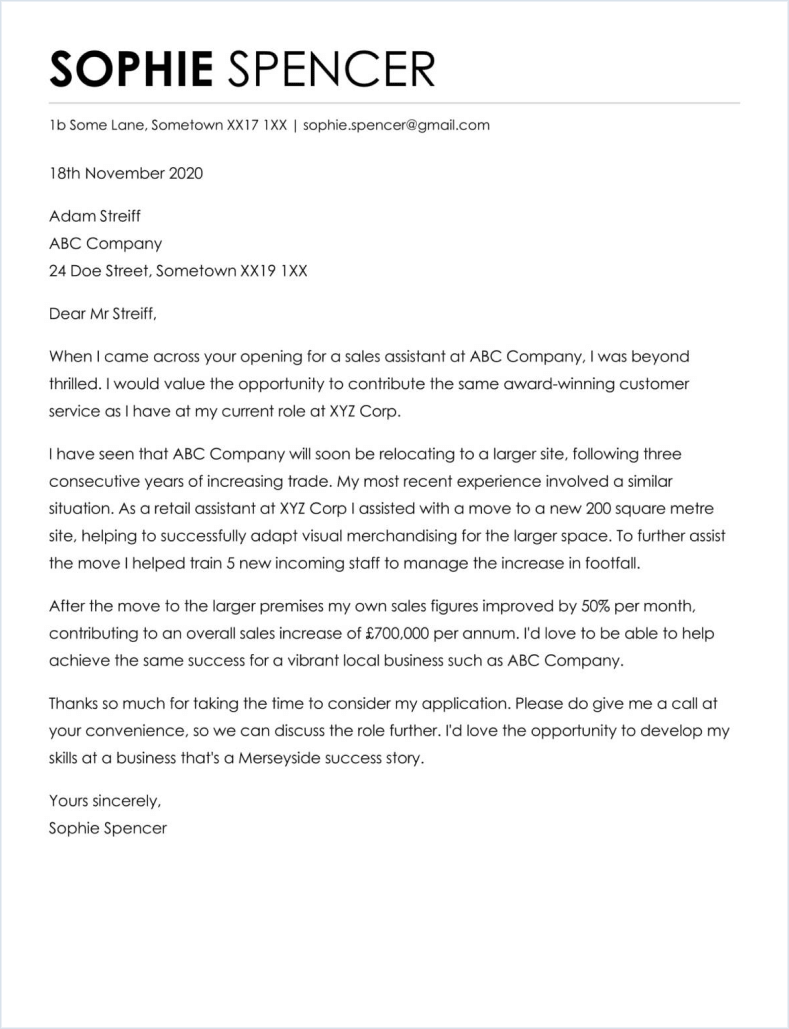

Interesting New Engine Design Or Rather Newish Seems Like A Modification Of Old Radial Airplane Engines These Guy Engineering Technology Combustion Engine From pinterest.com

Interesting New Engine Design Or Rather Newish Seems Like A Modification Of Old Radial Airplane Engines These Guy Engineering Technology Combustion Engine From pinterest.com

After both motors were completely designed they were simulated three dimensionally through the FEM and the. Each OEM is looking at specific configurations as the different size and form factor of the axial motor changes the design of an EV. Ultimately we ended up with a double stator single rotor Axial Flux brushless motor.

That opens up new design options within the vehicle platform such as where to place the battery packs.

The internal rotating structure carries the majority of reciprocating inertial loads so the external engine. Axial-flux motor designs also impact electromagnetics characteristics because magnetic flux travels shorter distances. The motors higher power density means that a smaller axial motor can be used compared to a radial motor. The internal rotating structure carries the majority of reciprocating inertial loads so the external engine. Making those improvements is trickier in radial motors with an in-runner design where the rotor is inside the stator. This engine with its small design less than 1 inch thick.

Another Article :

While YASA Saietta and Magnax all claim that axial-flux technology is the way to go radial motor designs still hold their own in. This means for the same permanent magnet and copper winding provision you get more torque. Vastly less moving parts as compared to linear engine. Duke re-imagined the design utilizing a reciprocator converting the linear layout into a circular or axial configurationand the results are stunning. ARRAY ELECTRIC MOTOR model which is an axial flux electric motor with axis orientation perpendicular to the ground as shown in Figure 13 which in some cases simplifies mechanical assembly o change the direction of application of the torque. 5 Stage Axial Flow Micro Turbine The Worlds Most Advanced Micro Jet Here It Is The World S Most Advanced Micro Jet A Jet Engine Aircraft Design Jet Turbine.

After both motors were completely designed they were simulated three dimensionally through the FEM and the. Most of the parts are 3D printed the rotor and axle are milled. His brushed DC motor design held the magnets stationary with a spinning armature activated by sliding brushes as the rotor. This means for the same permanent magnet and copper winding provision you get more torque. New generation non-fossil fuels could work best with an all-new engine design–with the radial power plant making a comeback. Interesting New Engine Design Or Rather Newish Seems Like A Modification Of Old Radial Airplane Engines These Guy Engineering Technology Combustion Engine.

High torque density. What are the Advantages of Axial Flux Motor. This engine with its small design less than 1 inch thick. Axial flux motors were studied by British inventor and EV enthusiast Cedric Lynch as early as 1979. The axial engine architecture allows us to implement our constant volume combustion cycle delivers extremely low vibration in a convenient quasi-cylindrical package and we have overcome the traditional limitations associated with the configuration. Grogan And Company Full Details For Lot 1053 Machine A Vapeur Moteur Vapeur.

His brushed DC motor design held the magnets stationary with a spinning armature activated by sliding brushes as the rotor. Axial flux motors were studied by British inventor and EV enthusiast Cedric Lynch as early as 1979. According to Nevada-based Axial Vector Energy Corporation AVEC it has powerful lightweight and highly efficient radial-design engines capable of producing significantly higher horsepower and torque with considerably lower fuel requirements than is the case. The axial engine architecture allows us to implement our constant volume combustion cycle delivers extremely low vibration in a convenient quasi-cylindrical package and we have overcome the traditional limitations associated with the configuration. This means for the same permanent magnet and copper winding provision you get more torque. The Duke Axial Prototype Engine Has No Camshafts Pushrods Rocker Arms Valves Or Springs Can This Be The Motorcycle En Engineering Design Motorcycle Engine.

It was designed by Dr. His brushed DC motor design held the magnets stationary with a spinning armature activated by sliding brushes as the rotor. Each OEM is looking at specific configurations as the different size and form factor of the axial motor changes the design of an EV. After both motors were completely designed they were simulated three dimensionally through the FEM and the. In the axial flux design the magnets and stator are arranged with the poles parallel to the shafting and the flux directed axially hence the name. Axial Internal Combustion Engines Automobile Engineering Automotive Mechanic Mechanical Engineering Projects.

Because the axial and transverse motor designs can have the rotating member located on their outer diameter they create higher torque while reducing their motor footprint. In the axial flux design the magnets and stator are arranged with the poles parallel to the shafting and the flux directed axially hence the name. We are a manufacturing and development company whose main products are innovative axial flux e-motors. New generation non-fossil fuels could work best with an all-new engine design–with the radial power plant making a comeback. Axial flux motors were studied by British inventor and EV enthusiast Cedric Lynch as early as 1979. Duke Engines Axial Valveless 5 Cylinder Engine Pretty Neat Axial Radial Engine Engineering.

According to Nevada-based Axial Vector Energy Corporation AVEC it has powerful lightweight and highly efficient radial-design engines capable of producing significantly higher horsepower and torque with considerably lower fuel requirements than is the case. Vastly less moving parts as compared to linear engine. The axial engine architecture allows us to implement our constant volume combustion cycle delivers extremely low vibration in a convenient quasi-cylindrical package and we have overcome the traditional limitations associated with the configuration. The magnetic and electrical design of the new motor and the conventional axial-flux permanent-magnet motor were evaluated considering nominal values. Compact structure especially short axial sizes. Axial Steam Engines Mechanical Design Automotive Engineering Steam Engine.

High power density. What are the Applications of Axial Flux Motor. We are a manufacturing and development company whose main products are innovative axial flux e-motors. Lightweight compact and relatively powerful the motor was ideal for electric motorcycles. Axial flux motors were studied by British inventor and EV enthusiast Cedric Lynch as early as 1979. Trebert Axial Engine Automotive Engineering Engineering Combustion Engine.

We are a manufacturing and development company whose main products are innovative axial flux e-motors. This means for the same permanent magnet and copper winding provision you get more torque. 5 cylinders require only 3 spark plugs but have as many power strokes per rotation as a 6 cylinder traditional. Besides our motors stand out from other axial flux motors in exceptional high power torque density low weight and compact design. What are the Applications of Axial Flux Motor. Duke Axial Prototype The Ultimate Motorcycle Engine Design Up To Speed Automotive Engineering Motorcycle Engine Engineering.

This video features inventor Roy Pfieffer. Radial-flux Motors Hold Their Own. After both motors were completely designed they were simulated three dimensionally through the FEM and the. To sum up the axial flux motor has the following advantages. The motors higher power density means that a smaller axial motor can be used compared to a radial motor. Axial Internal Combustion Engines Aluminium Materials By Braidy Industries Engineering Combustion Engine Vehicle Design.

His brushed DC motor design held the magnets stationary with a spinning armature activated by sliding brushes as the rotor. Vastly less moving parts as compared to linear engine. Axial-flux motor designs also impact electromagnetics characteristics because magnetic flux travels shorter distances. Ultimately we ended up with a double stator single rotor Axial Flux brushless motor. Axial flux motors were studied by British inventor and EV enthusiast Cedric Lynch as early as 1979. Axial Internal Combustion Engines Aluminium Materials By Braidy Industries Combustion Engine Engineering Mechanical Design.

The axial design offers complete primary balance and negligible secondary vibration. The internal rotating structure carries the majority of reciprocating inertial loads so the external engine. New generation non-fossil fuels could work best with an all-new engine design–with the radial power plant making a comeback. With an axial-flux design theres a larger radius than in a conventional radial motor you get more torque for the same force. High torque density. Axial Internal Combustion Engines Aluminium Materials By Braidy Industries Mechanical Design Combustion Engine Vehicle Design.

This aspect of axial-flux motor design typically deli vers a 30 torque density advantage over a conventional radial motor. After both motors were completely designed they were simulated three dimensionally through the FEM and the. His brushed DC motor design held the magnets stationary with a spinning armature activated by sliding brushes as the rotor. The off-set in the number of poles P16 and the number of coils C15 creates three distinct phase peaks A B and C. This video features inventor Roy Pfieffer. Axial Internal Combustion Engines Aluminium Materials By Braidy Industries Combustion Engine Engineering Vehicle Design.

What are the Applications of Axial Flux Motor. This aspect of axial-flux motor design typically deli vers a 30 torque density advantage over a conventional radial motor. New generation non-fossil fuels could work best with an all-new engine design–with the radial power plant making a comeback. His brushed DC motor design held the magnets stationary with a spinning armature activated by sliding brushes as the rotor. That opens up new design options within the vehicle platform such as where to place the battery packs. Delorean S Next Radical Idea Was This Never Before Seen Engine Automotive Engineering Engineering Mechanical Engineering.

Making those improvements is trickier in radial motors with an in-runner design where the rotor is inside the stator. The motor will be controlled by a 3 cycle. Duke re-imagined the design utilizing a reciprocator converting the linear layout into a circular or axial configurationand the results are stunning. Axial flux motors were studied by British inventor and EV enthusiast Cedric Lynch as early as 1979. Because the axial and transverse motor designs can have the rotating member located on their outer diameter they create higher torque while reducing their motor footprint. Unusual Engine Designs Imgur Engineering Mechanical Engineering Mechanical Design.