In ATR H2 or H 2 -enriched gas is injected along with steam to produce CH 4. 2 these two main drawbacks were considered and overcome. autothermal reformer design.

Autothermal Reformer Design, The ATR AH2 makes use of an additional enthalpy flow coming from a flow of. Developed in the late 50s ATRs main application was for ammonia and methanol syntheses. An efficient and reliable conversion of the feedstock has a huge impact on the economics of the plant.

By eliminating the need for tubular reforming steam addition can be significantly reduced and energy efficiency is improved. In ATR H2 or H 2 -enriched gas is injected along with steam to produce CH 4. For the design and construction of Juelichs novel reactor type for autothermal reforming ATR AH2 as shown in Fig.

Proven autothermal reforming technology for modern large-scale methanol plants.

Application of autothermal reforming Autothermal reforming already established for syngas production. For the design and construction of Juelichs novel reactor type for autothermal reforming ATR AH2 as shown in Fig. Based on specific conditions of maximum waste heat recovery the optimization algorithm for maximizing hydrogen yield is obtained. A variety of reforming technologies that might be used in distributed hydrogen production at refueling stations are reviewed. By eliminating the need for tubular reforming steam addition can be significantly reduced and energy efficiency is improved. Autothermal reforming results in higher CO2 capture percentages and is more economical and therefore has great potential for debottlenecking existing facilities as well as configuring new effective blue hydrogen production plants.

Another Article :

Together with the high-temperature polymer electrolyte fuel cell the reactor for the autothermal reforming ATR of liquid hydrocarbons such as diesel fuel or kerosene is the key component of the Jülich fuel cell system in the 5kWe power class. Autothermal reforming results in higher CO2 capture percentages and is more economical and therefore has great potential for debottlenecking existing facilities as well as configuring new effective blue hydrogen production plants. Depending on customers needs mainly syngas composition or plant capacity Air Liquide Engineering Construction can provide ATR as a. Reformer and an oxygen-fired autothermal reformer where the heat of reaction is supplied by the hot gas exiting the autothermal reformer. Autothermal Cyclic Reforming H 2 Refueling 3 Objectives Overall Design a reformer based refueling system that can meet the DOE cost Fabricate and operate an integrated 60 kg of H 2day reforming and refueling system Last Year Design fabricate and operate reformer and pressure swing adsorber pilot-scale sub-systems. Apparatus And Use Thereof In The Production Of Synthesis Gas Patent 0271299.

The autothermal reforming of diesel fuel is a catalytic process that runs at temperatures of 700 C900 C. This paper presents some of Jülichs most recent development in the field of ATR reactors. The ATR can provide a. Download Full PDF Package. The process is soot-free due to burner design and fixed-bed catalyst. Heat Exchange Reforming Global Syngas Technologies Council.

1 Fundamental design of Juelichs established reactor type for autothermal reformer. Developed in the late 50s ATRs main application was for ammonia and methanol syntheses. Abstract The conceptual design of compact stand-alone autothermal reforming systems using methanol is presented. Autothermal reforming ATR is a low-investment process using a simple reactor design. The development of these auxiliary power units is based upon the use of. Advances In Autothermal Reformer Design Sciencedirect.

Our well-known side fired reforming furnaces specialized secondary reformer burners and high. Bottom fired Top fired foster wheeler terrace wall and side fired reformers. Together with the high-temperature polymer electrolyte fuel cell the reactor for the autothermal reforming ATR of liquid hydrocarbons such as diesel fuel or kerosene is the key component of the Jülich fuel cell system in the 5kWe power class. This paper discusses the preliminary modeling and design of an experimental autothermal reformer that will be used in several research projects at the University of California at Davis. A numerical study was carried out to improve the design of an autothermal reformer for the onboard production of hydrogen to be used in fuel-cell- powered auxiliary power units APU to provide heating and electricity in long haul trucks when they are at rest. 2.

1 Fundamental design of Juelichs established reactor type for autothermal reformer. Long-chain hydrocarbon molecules react with steam and O2 yielding a product gas. A numerical study was carried out to improve the design of an autothermal reformer for the onboard production of hydrogen to be used in fuel-cell- powered auxiliary power units APU to provide heating and electricity in long haul trucks when they are at rest. Reformer and an oxygen-fired autothermal reformer where the heat of reaction is supplied by the hot gas exiting the autothermal reformer. The autothermal reforming technology has been widely discussed in the past on con-ferences and in technical magazines. Methanol Production Using Vulcan Systems Combined Reforming Technolog.

Pre-treatment process Reformer reactor Shift reactor Gas purification process. Stand-alone ATR for GTL plants ATR combined with conventional tubular primary reformer for NH 3 and methanol plants. This design has the following advantages. By eliminating the need for tubular reforming steam addition can be significantly reduced and energy efficiency is improved. However further research is required to optimize the performance of autothermal reformers and accurate models of reactor performance must be developed and validated. Design Of The Autothermal Reforming Cycle In Aspen Plus Software Download Scientific Diagram.

A short summary of this paper. Download Full PDF Package. A numerical study was carried out to improve the design of an autothermal reformer for the onboard production of hydrogen to be used in fuel-cell- powered auxiliary power units APU to provide heating and electricity in long haul trucks when they are at rest. Steam reforming is a well-proven thoroughly de-bugged technology thats in widespread use worldwide. Followed by a purification step using in-house-standard 4 or 5-bed PSA technology. Recent Advances In Diesel Autothermal Reformer Design Sciencedirect.

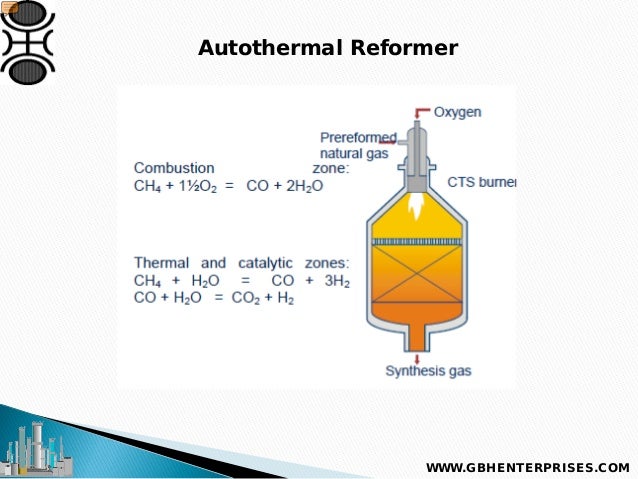

Our different reforming layouts can be tailor-made to meet the requirements of the client without compromising on reliability. Compared to the steam methane reformer SMR with its multitude of tubes the autothermal reformer ATR offers a much sim-pler mechanical setup and superior operational robustness. The ATR reactor vessel contains a combustion zone and a set catalyst bed among a refractory-lined pressure shell. Reforming is the dominant method for hydrogen production. Depending on customers needs mainly syngas composition or plant capacity Air Liquide Engineering Construction can provide ATR as a. Fired Tubular Reformer An Overview Sciencedirect Topics.

Together with the high-temperature polymer electrolyte fuel cell the reactor for the autothermal reforming ATR of liquid hydrocarbons such as diesel fuel or kerosene is the key component of the Jülich fuel cell system in the 5kWe power class. This is usually combined with PSA to purify the hydrogen to greater than 9999vol. Autothermal reforming ATR is a combination of SR and POR both reactions manifest themselves in one compact reactor. Overall Process Plant PRETREATMENT FEED PURIFICATION. Steam reforming is a well-proven thoroughly de-bugged technology thats in widespread use worldwide. Advances In Autothermal Reformer Design Sciencedirect.

With a SynCOR autothermal reformer tubular reforming is not necessary instead pre-reformed natural gas is sent directly to the autothermal reformer along with oxygen. Reformer and an oxygen-fired autothermal reformer where the heat of reaction is supplied by the hot gas exiting the autothermal reformer. The ATR can provide a. The ATR reactor vessel contains a combustion zone and a set catalyst bed among a refractory-lined pressure shell. Application of autothermal reforming Autothermal reforming already established for syngas production. Schematic Of Autothermal Rector Download Scientific Diagram.

2 these two main drawbacks were considered and overcome. Overall Process Plant PRETREATMENT FEED PURIFICATION. The autothermal reforming technology has been widely discussed in the past on con-ferences and in technical magazines. Reforming is the dominant method for hydrogen production. This design is very attractive at sites where low cost oxygen is available. Advances In Autothermal Reformer Design Sciencedirect.

Autothermal Cyclic Reforming H 2 Refueling 3 Objectives Overall Design a reformer based refueling system that can meet the DOE cost Fabricate and operate an integrated 60 kg of H 2day reforming and refueling system Last Year Design fabricate and operate reformer and pressure swing adsorber pilot-scale sub-systems. Mixture of pre-reformed gas and natural gas. The ATR AH2 makes use of an additional enthalpy flow coming from a flow of. A short summary of this paper. Overall Process Plant PRETREATMENT FEED PURIFICATION. Recent Developments In Autothermal Reforming And Pre Reforming For Synthesis Gas Production In Gtl Applications Sciencedirect.

Compared to the steam methane reformer SMR with its multitude of tubes the autothermal reformer ATR offers a much sim-pler mechanical setup and superior operational robustness. Now the reforming section can be compress only to adiabatic pre-reformer and tubular steam reformer where the tubular steam reformer is the main component. ATR used as secondary reformer on pre-reformed gas methanol. Abstract The conceptual design of compact stand-alone autothermal reforming systems using methanol is presented. Autothermal Cyclic Reforming H 2 Refueling 3 Objectives Overall Design a reformer based refueling system that can meet the DOE cost Fabricate and operate an integrated 60 kg of H 2day reforming and refueling system Last Year Design fabricate and operate reformer and pressure swing adsorber pilot-scale sub-systems. Controller Design And Experiment For Autothermal Reforming Of Methanol In Miniature Reactor Semantic Scholar.

Mixture of pre-reformed gas and natural gas. Our well-known side fired reforming furnaces specialized secondary reformer burners and high. Application of autothermal reforming Autothermal reforming already established for syngas production. For the design and construction of Juelichs novel reactor type for autothermal reforming ATR AH2 as shown in Fig. Developed in the late 50s ATRs main application was for ammonia and methanol syntheses. Autothermal Reformer An Overview Sciencedirect Topics.

Pre-treatment process Reformer reactor Shift reactor Gas purification process. 41 Configuration of Steam reformers Reformers can be categorized in to 4 main types according to the configuration. The ATR AH2 makes use of an additional enthalpy flow coming from a flow of. Proven autothermal reforming technology for modern large-scale methanol plants. Our well-known side fired reforming furnaces specialized secondary reformer burners and high. Simplified Schematic Of Autothermal Reforming System Download Scientific Diagram.