Last previous edition approved in 2011 as C685C685M11. Manufactured Concrete Pipe 60-80 Packerhead Mix 45-65 Dry Cast. astm concrete mix design.

Astm Concrete Mix Design, Recordation to the theoretical mix design submitted and approved by the. Secondly a choice must be made between specifying proportions or properties listed in ASTM C270. 150150 of 200 psi 14 MPa in a 4000 psi 28 MPa concrete mixture.

Quikrete 90 Lb High Strength Concrete Mix Lowes Com In 2021 Concrete Mixes Concrete Diy Concrete Projects From pinterest.com

Quikrete 90 Lb High Strength Concrete Mix Lowes Com In 2021 Concrete Mixes Concrete Diy Concrete Projects From pinterest.com

Practical Concrete Mix Design has been compiled to help readers understand the concrete mix design methodology including formulas and tables involved in the pertinent steps. ASTM standards are designed to allow a meeting of the minds between the purchaser and the vendor. SCC - Flow Rate T.

For example use fiber at a dosage to provide a minimum residual strength 𝑓𝑓.

Of ACI Committee 229 or the National Ready Mixed Concrete Association. Secondly a choice must be made between specifying proportions or properties listed in ASTM C270. The main body of the guidelines focuses on the process of reviewing the mix design. ASTM C476 determines the types of cement sands aggregates water and other additives that the contractor can use in the material mix design and how to proportion these components. Of the limitations of SCC is that there is no established mix design procedure yet. The concrete mix design involves various steps calculations and laboratory testing to find right mix proportions.

Another Article :

In addition to meeting the standard the contractor ensures that the masonry grout is compatible with any grouting equipment used on the project such as mortar mixers delivery systems and grout pumps. And 3 the inclusion exclusion or limits on specific ingredients. 150150 of 200 psi 14 MPa in a 4000 psi 28 MPa concrete mixture. We would like to show you a description here but the site wont allow us. These guidelines were developed to assist the engineer reviewing concrete mix designs. Sakrete 50 Lb Fast Setting Concrete Mix Lowes Com Fast Setting Concrete Concrete Mixes Concrete.

Of the limitations of SCC is that there is no established mix design procedure yet. Secondly a choice must be made between specifying proportions or properties listed in ASTM C270. While designing a mix consideration should be given on the desired strength durability and workability of the concrete for the project in question. So concrete mix design can be stated as Concrete Mix CementSandAggregates. Integration of the asphalt concrete mix design procedure can be achieved through interaction between pavement distress identification desired mix design parameters and selection of criteria and territorial constraints including economic technological physical and human resources capabilities. Pin On Products.

Portland cement-lime mortars are specified in two steps. Secondly a choice must be made between specifying proportions or properties listed in ASTM C270. 12 Basis of. It provides a clear indication of which amount to be used for each type of material. Specifying designing and proportioning ACI Mix Design The most common method used in North America is that established by ACI Recommended Practice 2111 Any mix design procedure will provide a first approximation. Sakrete 94 Lb I Ii Cement Lowes Com Portland Cement Cement Concrete Diy Projects.

Of ACI Committee 229 or the National Ready Mixed Concrete Association. Designing Concrete Mixtures There are three phases in the development of a concrete mixture. A concrete mix design refers to a method of choosing constituents for a concrete mixture and deciding on their proportions. Of the limitations of SCC is that there is no established mix design procedure yet. Concrete mix design is the indication of concrete mix propositions including the type of admixtures used concrete slump etc. Sakrete 5000 Plus 80 Lb High Strength Concrete Mix Lowes Com High Strength Concrete Concrete Mixes Concrete.

A concrete mix design refers to a method of choosing constituents for a concrete mixture and deciding on their proportions. Concrete mix design is the indication of concrete mix propositions including the type of admixtures used concrete slump etc. And 3 the inclusion exclusion or limits on specific ingredients. These guidelines were developed to assist the engineer reviewing concrete mix designs. The concrete mix design involves various steps calculations and laboratory testing to find right mix proportions. Fast Setting Concrete Mix Recipe Ingredients Mix Design Fast Setting Concrete Concrete Mixes Concrete.

And 3 the inclusion exclusion or limits on specific ingredients. Specifying designing and proportioning ACI Mix Design The most common method used in North America is that established by ACI Recommended Practice 2111 Any mix design procedure will provide a first approximation. ASTM C476 determines the types of cement sands aggregates water and other additives that the contractor can use in the material mix design and how to proportion these components. While designing a mix consideration should be given on the desired strength durability and workability of the concrete for the project in question. Record of the time it takes for the outer edge of the concrete massouter edge of the concrete mass to reach a diameter of 20. Used By Made By Barb For Bowls Rapid Set 55 Lb Cement All Multi Purpose Construction Material 02010055 The Ho Cement Construction Materials Concrete Mixes.

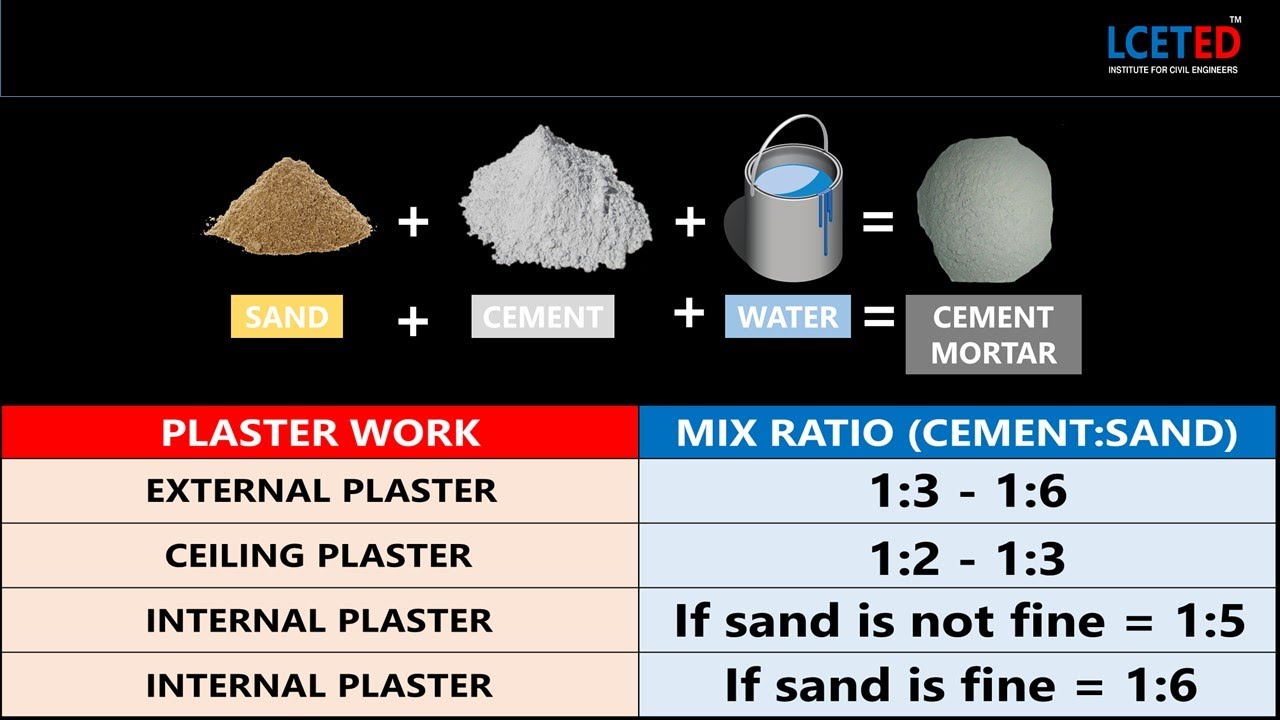

For example use fiber at a dosage to provide a minimum residual strength 𝑓𝑓. A concrete mix design refers to a method of choosing constituents for a concrete mixture and deciding on their proportions. Concrete mix designs are submitted for review so that the reviewer can verify the contractor is interpreting the construction documents correctly. Last previous edition approved in 2011 as C685C685M11. Of the limitations of SCC is that there is no established mix design procedure yet. Cement Mortar Mix Ratio And Its Application Lceted Mixratio In 2021 Engineering Notes Civil Engineering Design Civil Engineering Handbook.

Concrete mix design is the process of selecting suitable ingredients of concrete and determine the relative proportions to produce concrete with certain performance and durability requirements. 150150 of 200 psi 14 MPa in a 4000 psi 28 MPa concrete mixture. Designing Concrete Mixtures There are three phases in the development of a concrete mixture. ASTM C476 determines the types of cement sands aggregates water and other additives that the contractor can use in the material mix design and how to proportion these components. Last previous edition approved in 2011 as C685C685M11. Portland Cement High Temperature Mortar Ingredient Portland Cement Cement Bag Of Cement.

150150 of 200 psi 14 MPa in a 4000 psi 28 MPa concrete mixture. Calculations are conducted for the design of FRC parameters such as residual strength must be used for specification. This book helps engineers understand the mix design procedure through illuminating every possible explanation for each step of mix design limitations given by standards and practical guides on tailor-making concrete to. Of the limitations of SCC is that there is no established mix design procedure yet. ASTM C 90 Standard Specification for Load-Bearing Concrete Masonry Units. Sakrete 5000 Plus 80 Lb Concrete Mix 65200370 The Home Depot Concrete Mixes Concrete Concrete Mix Design.

Most project specifications will cite many material standards for the materials that go into making concrete ASTM C150 Cement C618 Fly ash C989 Slag C494 Admixtures C33 for Aggregate and so on. Calculations are conducted for the design of FRC parameters such as residual strength must be used for specification. Entrained C LSM mixtures. We would like to show you a description here but the site wont allow us. Last previous edition approved in 2011 as C685C685M11. Quikrete 50 Lb Fast Setting Concrete Mix Lowes Com Fast Setting Concrete Concrete Mixes Concrete.

Record of the time it takes for the outer edge of the concrete massouter edge of the concrete mass to reach a diameter of 20. 20 APPLICABLE DOCUMENTS R20 APPLICABLE DOCUMENTS 21 ASTM Standards C 403 The intent of the guide is to use the most current Time of Setting. Most project specifications will cite many material standards for the materials that go into making concrete ASTM C150 Cement C618 Fly ash C989 Slag C494 Admixtures C33 for Aggregate and so on. Entrained C LSM mixtures. Originally approved in 1971. Pin On Casa Tips Before Sale.

The concrete mix design involves various steps calculations and laboratory testing to find right mix proportions. While designing a mix consideration should be given on the desired strength durability and workability of the concrete for the project in question. In addition to meeting the standard the contractor ensures that the masonry grout is compatible with any grouting equipment used on the project such as mortar mixers delivery systems and grout pumps. Practical Concrete Mix Design has been compiled to help readers understand the concrete mix design methodology including formulas and tables involved in the pertinent steps. 1828 ft Sand to Aggregate Ratio Volume of Sand Volume of Total Aggregate Rules of thumb. Download The Specifications For Reinforcement Steel Best Online Engineering Resource Reinforcement Steel Steel Bar.

Secondly a choice must be made between specifying proportions or properties listed in ASTM C270. This paper describes a procedure specifically developed to achieve self-compacting concrete. Current edition approved Dec. Concrete mix design is the process of selecting suitable ingredients of concrete and determine the relative proportions to produce concrete with certain performance and durability requirements. Of ACI Committee 229 or the National Ready Mixed Concrete Association. Sakrete 60 Lb All Purpose Concrete Mix Lowes Com In 2021 High Strength Concrete Concrete Mixes Concrete.

Practical Concrete Mix Design has been compiled to help readers understand the concrete mix design methodology including formulas and tables involved in the pertinent steps. In addition the test results for acceptance characteristics for self-compacting concrete such as slump flow J-ring V-funnel and L-Box are presented. This article gives general guide-lines for designing a concrete mix with locally available aggregates and focuses on determining aggre-gate fineness modulus proportion-. Mix design with Cement Fly Ash Volume without aggregate 872 2700 - 872 18 28 ft3 required Its about volume. ASTM C 90 Standard Specification for Load-Bearing Concrete Masonry Units. Quikrete Quikrete 70 Lb N Cement In Gray 112570 In 2021 Cement Masonry Stucco Mix.

Most project specifications will cite many material standards for the materials that go into making concrete ASTM C150 Cement C618 Fly ash C989 Slag C494 Admixtures C33 for Aggregate and so on. Product descriPtion DESIGNMIX Professional-Grade Mortar Mix is a specially blended portland cementlime based mortar mix that when prepared properly will result in a mortar that conforms to the Property Specification requirements of ASTM C270 Standard Specification for Mortar for Unit Masonry and the requirements of ASTM C1714C1714M Standard. ASTM C476 determines the types of cement sands aggregates water and other additives that the contractor can use in the material mix design and how to proportion these components. For example use fiber at a dosage to provide a minimum residual strength 𝑓𝑓. This book helps engineers understand the mix design procedure through illuminating every possible explanation for each step of mix design limitations given by standards and practical guides on tailor-making concrete to. Quikrete 90 Lb High Strength Concrete Mix Lowes Com In 2021 Concrete Mixes Concrete Diy Concrete Projects.