Pressure 200 PSIG Temperature -20F To 150F Corrosion Allowance Zero Tube. In addition many process in the pharmaceutical chemical and food processing industries require secure gas supplies for optimum results. argon gas piping design.

Argon Gas Piping Design, Physical properties and system design of gas extinguishing systems for IG-541 extinguishant Components used in the system that use extinguishing agent Argon IG01 Nitrogen IG100 NitrogenArgon IG55 and NitrogenArgonCO 2 IG541 are. For welding and cutting the right mode of supply reduces costs and minimize downtime to help ensure maximum efficiency. Argon is an expensive gas and is used in applications such as arc welding where nitrogen may react with the electric arc.

Gutter Downspout Underground Drainage Installion Repair Buried Drain Pipes For Draining Water Underground Drainage Drainage Solutions Backyard Drainage From pinterest.com

Gutter Downspout Underground Drainage Installion Repair Buried Drain Pipes For Draining Water Underground Drainage Drainage Solutions Backyard Drainage From pinterest.com

30122 - Required Pressure Containment or Relief. Many manufacturing applications use argon or nitrogen gas for inert purging and blanketing. Gases such as silane phosphine diborane and arsine are commonly used in the semi-conductor industry and are extremely dangerous to handle because they do not require a source of ignition to explode or catch fire.

Argon is an expensive gas and is used in applications such as arc welding where nitrogen may react with the electric arc.

The piping used in oxygen piping system design must be cleaned before the use as well as after the set up. Large inside diameters provide excellent flow rates. Piping systems in other industries covered in the ASME B313 Code include piping typically found in petroleum re-fineries chemical textile and paper plants that for the most part consist of metallic pipe installed with multipass manual welds with filler metal added to the weld. This unique pipe design provides high strength and pressure ratings while offering the benefits of a pipe that bends easily and stays bent. 30122 - Required Pressure Containment or Relief. This means it will not react with any substance easily.

Another Article :

This unique pipe design provides high strength and pressure ratings while offering the benefits of a pipe that bends easily and stays bent. The tables and figures referenced within this article could not be reproduced online. For welding and cutting the right mode of supply reduces costs and minimize downtime to help ensure maximum efficiency. The designer must address all design conditions. Of all the design considerations listed in 301 only pressure rating is covered in the Piping Specifications in Appendix A. We Offer Bulk Gasses Welding Supplies Welding Gas Welding.

The pipe flow calculation can compute flow rate velocity pipe diameter elevation difference pressure difference pipe length minor loss coefficient and pump head total dynamic head. Large inside diameters provide excellent flow rates. Protective equipment including a flashback arrester is required in fuel gas and oxygen piping systems to prevent a reverse flow of oxygen from flowing back up the fuel gas line or a reverse flow of fuel gas from flowing back up the oxygen line also to prevent excessive pressure build-up in the system and stop a flashback from reaching the supply source. Argon is an expensive gas and is used in applications such as arc welding where nitrogen may react with the electric arc. Many manufacturing applications use argon or nitrogen gas for inert purging and blanketing. Boilermaker B W Rear Wall Steam Boiler Scroll Wall Art Metal Art Welded.

Pyrophoric gases will ignite spontaneously in air at or below 130F 54C. This unique pipe design provides high strength and pressure ratings while offering the benefits of a pipe that bends easily and stays bent. The designer must address all design conditions. Central gas supply systems designs for laboratories depends on accurate pressure control flow requirement and contamination free gas piping components like high pressure gas regulator point of use regulator for gas distribution within the laboratory. D N design custom piping systems to distribute compressed gases including nitrogen argon helium and other inert gases. Sip Panel Walls Are Less Susceptible To Air Leakage And Convection And Resultant Potential Condensatio Structural Insulated Panels Insulated Panels Sips Panels.

Specific gases may not ignite in all circumstances or may. Piping systems in other industries covered in the ASME B313 Code include piping typically found in petroleum re-fineries chemical textile and paper plants that for the most part consist of metallic pipe installed with multipass manual welds with filler metal added to the weld. In addition many process in the pharmaceutical chemical and food processing industries require secure gas supplies for optimum results. Gases such as silane phosphine diborane and arsine are commonly used in the semi-conductor industry and are extremely dangerous to handle because they do not require a source of ignition to explode or catch fire. Copper-to-copper joints shall be made using a copper-phosphorus brazing filler metal BCuP series without flux. Selecting Gas Delivery Systems For Safety Performance And Cost Efficiency In The Laboratory American Laboratory.

The tables and figures referenced within this article could not be reproduced online. The tables and figures referenced within this article could not be reproduced online. Piping systems in other industries covered in the ASME B313 Code include piping typically found in petroleum re-fineries chemical textile and paper plants that for the most part consist of metallic pipe installed with multipass manual welds with filler metal added to the weld. The Piping Specifications provide materials fittings and fasteners which meet the pressure design requirements of B313. 30122 - Required Pressure Containment or Relief. We Are Gas Piping Specialist Commercial Kitchen Equipment Kitchen Solutions Stainless Steel Fabrication.

Each Gas Management System is designed as a discrete unit that can be integrated with Inert Glove Boxes. This specification is for the design installation test and repair of the shipyard C-5 system piping from the gas mixing stations to the service connection on the piping system. Argon is an expensive gas and is used in applications such as arc welding where nitrogen may react with the electric arc. This manual is a comprehensive guide containing all recommendations necessary to design and install the Argon IG01 Nitrogen IG100 NitrogenArgon IG55 e NitrogenArgonCO2 IG541 Gas Extinguishing Systems. This unique pipe design provides high strength and pressure ratings while offering the benefits of a pipe that bends easily and stays bent. This Beautiful And Super Strong 2 Burner Glass Gas Cooker 12 5 Kg Gas Cylinder Is Designed And Built With A Brass Valve Which Ma Cylinder Gas Hose Clean Pots.

30122 - Required Pressure Containment or Relief. This specification is for the design installation test and repair of the shipyard C-5 system piping from the gas mixing stations to the service connection on the piping system. The tables and figures referenced within this article could not be reproduced online. More than just a gas purification system these closed-loop designs enable the easy control monitoring and recycling of your argon or nitrogen working gas. Protective equipment including a flashback arrester is required in fuel gas and oxygen piping systems to prevent a reverse flow of oxygen from flowing back up the fuel gas line or a reverse flow of fuel gas from flowing back up the oxygen line also to prevent excessive pressure build-up in the system and stop a flashback from reaching the supply source. Inert Gas Piping Systems.

The pipe flow calculation can compute flow rate velocity pipe diameter elevation difference pressure difference pipe length minor loss coefficient and pump head total dynamic head. Argon is a noble gas which is completely inert. The tables and figures referenced within this article could not be reproduced online. The Piping Specifications provide materials fittings and fasteners which meet the pressure design requirements of B313. If required the argon gas pipe can be replaced by a krypton one thus extending the generation spectrum of the laser up to 753 nm. Choosing The Correct Gas Delivery System For Metalworking.

The Piping Specifications provide materials fittings and fasteners which meet the pressure design requirements of B313. Gaseous Nitrogen Cooling Water Instrument Air Design Conditions. Large inside diameters provide excellent flow rates. Protective equipment including a flashback arrester is required in fuel gas and oxygen piping systems to prevent a reverse flow of oxygen from flowing back up the fuel gas line or a reverse flow of fuel gas from flowing back up the oxygen line also to prevent excessive pressure build-up in the system and stop a flashback from reaching the supply source. The density and viscosity of a variety of liquids and gases are coded into the pipe flow program but you can alternatively select User defined fluid and enter the density and viscosity for fluids not listed. Gutter Downspout Underground Drainage Installion Repair Buried Drain Pipes For Draining Water Underground Drainage Drainage Solutions Backyard Drainage.

This means it will not react with any substance easily. The Piping Specifications provide materials fittings and fasteners which meet the pressure design requirements of B313. The pipe flow calculation can compute flow rate velocity pipe diameter elevation difference pressure difference pipe length minor loss coefficient and pump head total dynamic head. All brazed joints in the piping shall be made up using brazing filler metals that bond with the base metals being brazed and that comply with Specification for Brazing Filler Metal ANSIAWS A58. This unique pipe design provides high strength and pressure ratings while offering the benefits of a pipe that bends easily and stays bent. Instagram Photo By Weldporn Weldporn Via Iconosquare Welding Gear Tig Welding Welding Supplies.

C-5 Mixed Gas 95 Argon with 5 Carbon Dioxide Scope. The designer must address all design conditions. Test Requirements and Conceptual Design for a Potassium Test Loop to Support an Advanced Potassium Rankine Cycle Power Conversion Systems. Many manufacturing applications use argon or nitrogen gas for inert purging and blanketing. C-5 Mixed Gas 95 Argon with 5 Carbon Dioxide Scope. Cryotank Or Cryogenic Tank That Is Used To Store Frozen Biological Material Liquid Oxygen Cryogenic Liquid Nitrogen.

In this manual system refers to the extinguishing equipment and does not include any electrical system. The piping used in oxygen piping system design must be cleaned before the use as well as after the set up. This specification is for the design installation test and repair of the shipyard C-5 system piping from the gas mixing stations to the service connection on the piping system. Argon is a noble gas which is completely inert. Argon is an expensive gas and is used in applications such as arc welding where nitrogen may react with the electric arc. Weld Gas Installation Air Energy.

Specification for Piping Design Materials C2 PIPING DESIGN AND MATERIAL SPECIFICATION Service. Piping systems in other industries covered in the ASME B313 Code include piping typically found in petroleum re-fineries chemical textile and paper plants that for the most part consist of metallic pipe installed with multipass manual welds with filler metal added to the weld. In addition many process in the pharmaceutical chemical and food processing industries require secure gas supplies for optimum results. Specific gases may not ignite in all circumstances or may. More than just a gas purification system these closed-loop designs enable the easy control monitoring and recycling of your argon or nitrogen working gas. Smith 1 4 Inert Gas Replacement Hose 6 Ft 7294 1 In 2021 Inert Gas Gas Hose Welding Gas.

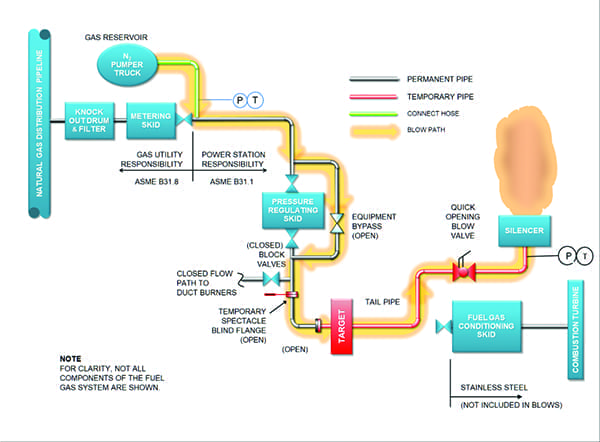

In addition many process in the pharmaceutical chemical and food processing industries require secure gas supplies for optimum results. Test Requirements and Conceptual Design for a Potassium Test Loop to Support an Advanced Potassium Rankine Cycle Power Conversion Systems. Copper-to-copper joints shall be made using a copper-phosphorus brazing filler metal BCuP series without flux. This means it will not react with any substance easily. Gaseous Nitrogen Cooling Water Instrument Air Design Conditions. How To Clean Natural Gas Piping With Gas Blows.

Piping systems in other industries covered in the ASME B313 Code include piping typically found in petroleum re-fineries chemical textile and paper plants that for the most part consist of metallic pipe installed with multipass manual welds with filler metal added to the weld. We have a range of pipes and fittings from 20 Bar to 70 Bar pressures in push fit design to cater to these requirementsThe piping is simple to install and easy to modify expand. Copper-to-copper joints shall be made using a copper-phosphorus brazing filler metal BCuP series without flux. Nothing downstream of the main shut-off valve of the facility such as tanks source arrangements and equipment or system. 30122 - Required Pressure Containment or Relief. Choosing The Correct Gas Delivery System For Metalworking.