The success of Tenova Melt Shops Business Line Electric Arc Furnaces is based on an intrinsically sensible and performing design concept for reliable long-life furnaces with a sturdy mechanical structure. A new design method for high-impedance electric arc furnace transformer voltages and rated current is put forward. arc furnace transformer design.

Arc Furnace Transformer Design, The position 21 ratio is 30 kV1154 V. Design of submerged arc furnaces with particular reference to production of high-silicon alloys by TE. After the reactor short-circuit in order to ensure electrical efficiency.

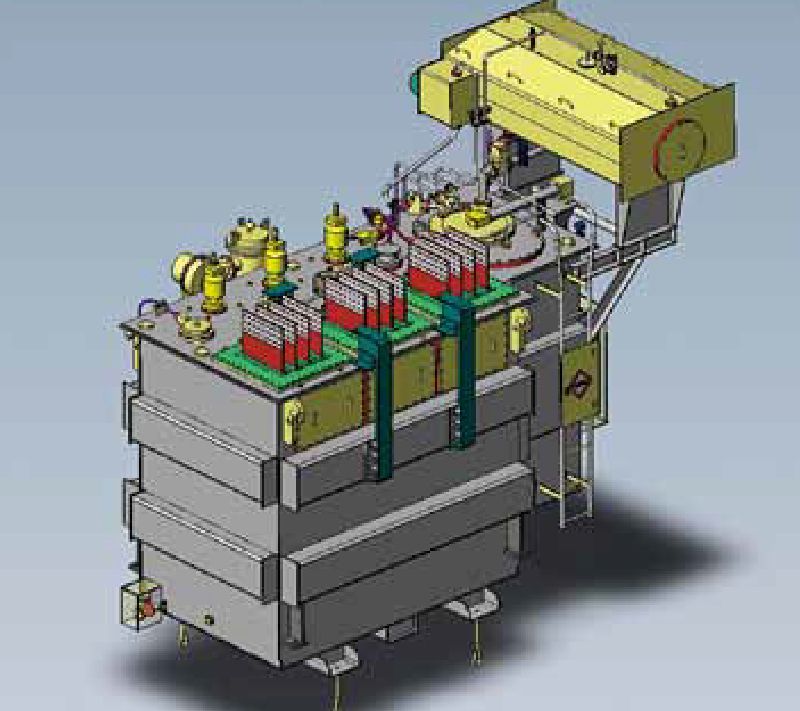

Furnace Transformers Nts Norsk Trafo Service As From norsktrafoservice.com

Furnace Transformers Nts Norsk Trafo Service As From norsktrafoservice.com

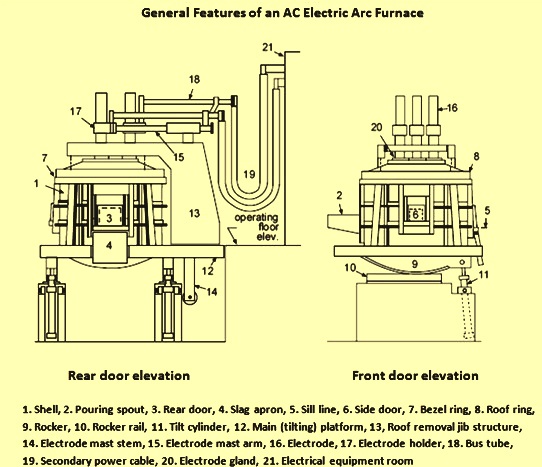

Sized electric arc furnaces were used as a guide in the design of this prototype. Optimum Design of Arc Furnace Secondary Conductors VII. Furnace charging Melting Refining De-slagging Tapping Furnace turn-around Modern operations aim for a tap-to-tap time of less than 60 minutes.

Furnace Transformer The transformer for electric arc furnace steelmaking shall be able to adjust the voltage and current separately according to the smelting requirements and be able to withstand the impact of working short-circuit current.

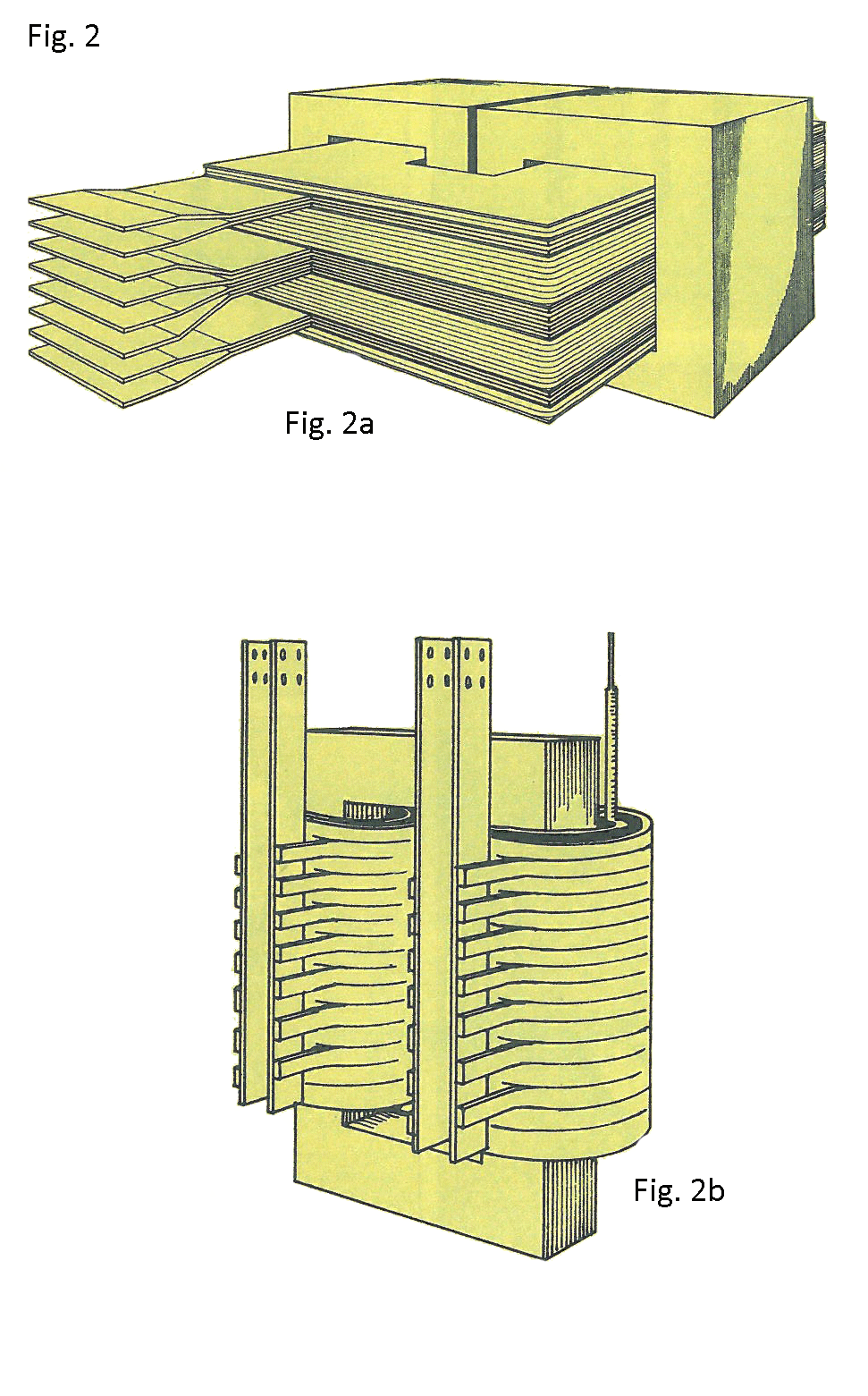

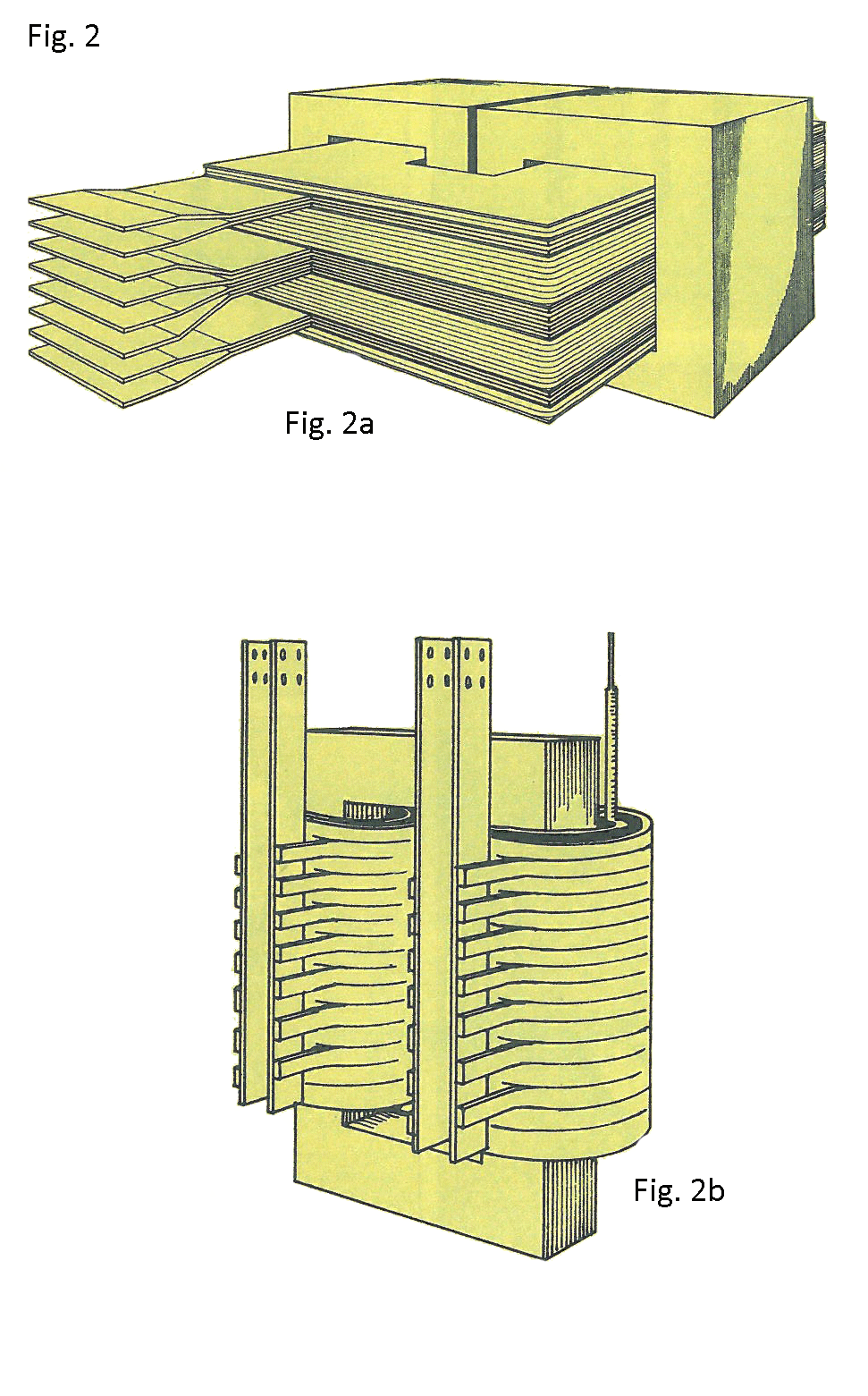

Furnaces transformers life is affected by heavy stresses during operation. Design of submerged arc furnaces with particular reference to production of high-silicon alloys by TE. A robust design guarantees mechanical strength for steel furnace operation and temperature control for continuous high loads in ferro-alloy operation. Sized electric arc furnaces were used as a guide in the design of this prototype. The step voltages will be larger than for an AC furnace transformer and a. Electric Arc Furnace Transformer Secondary Circuit Calculations 185 22 EAF electric circuit parameters The EAF that is subject of analysis has a step down 100 MVA furnace transformer with 21 tap positions.

Another Article :

The innovative TDRH digital electrode regulation system provides a. We produces transformers for all furnace applications counting long-arc steel and short-arc ferro-alloy operationA robust design ensures mechanical quality for steel furnace operation and temperature control for nonstop high loads in ferro-alloy operationArc heaters vary from acceptance heaters in that the charge fabric is specifically uncovered to an electric arc and the current within. Electric arc furnace EAF used for steel making apply high current and low voltage electric energy to the charge materials and thereby melt and refine them. DESIGN THEORY AND CALCULATIONS. Some twin shell furnace operations are achieving tap-to-tap times of 35 to 40 minutes. Life Assessment Of Electric Arc Furnace Transformers Semantic Scholar.

We produces transformers for all furnace applications counting long-arc steel and short-arc ferro-alloy operationA robust design ensures mechanical quality for steel furnace operation and temperature control for nonstop high loads in ferro-alloy operationArc heaters vary from acceptance heaters in that the charge fabric is specifically uncovered to an electric arc and the current within. Arc Submerged Arc Ladle Induction Upto 10 MVAUpto 33kVONANOFWF Cooling A high current furnace transformer is provided by having the low-voltage windings arranged in a closed delta configuration within the transformer enclosure. Optimum Design of Arc Furnace Secondary Conductors VII. For tap position 15. The reactance must be taken into account when designing the transformers for a new furnace. Furnace Transformers Nts Norsk Trafo Service As.

The mentioned transformer is designed in order to allow operation of the arcs at the desired range of arc voltages and currents. Recent examples of arc furnace transformer failures illustrate. There are many factors to be considered in the selection of rated voltage of furnace transformer. The furnace reactance affects the required transformer capacity as well as the. During EAF operation there are varying needs of arc voltagecurrent configuration through and for this reason its necessary to have the correct choice of the secondary voltages. Electric Arc Furnace Electrical4u.

The techniques of the operation and the unusual loads they produce are so severe particularly on the transformer that special design requirements and later the maintenance of the units is essential. Design of submerged arc furnaces with particular reference to production of high-silicon alloys by TE. A robust design guarantees mechanical strength for steel furnace operation and temperature control for continuous high loads in ferro-alloy operation. The mentioned transformer is designed in order to allow operation of the arcs at the desired range of arc voltages and currents. The utility to the step down transforme r the arc furnace transformer and the. Electric Arc Furnace Design Operation And Working Principle Bright Hub Engineering.

Frequent on and off switching high magnitude inrush currents. Frequent on and off switching high magnitude inrush currents. The step voltages will be larger than for an AC furnace transformer and a. Electric Arc Furnace Transformer Secondary Circuit Calculations 185 22 EAF electric circuit parameters The EAF that is subject of analysis has a step down 100 MVA furnace transformer with 21 tap positions. For tap position 15. Electric Arc Furnace Ac Part 1 Layout Components.

Rectifier Transformers face high operating currents combined with a huge amount of harmonic content due to the distorted waveform caused by the semiconductor converters connected to the transformer. During EAF operation there are varying needs of arc voltagecurrent configuration through and for this reason its necessary to have the correct choice of the secondary voltages. The utility to the step down transforme r the arc furnace transformer and the. An electric arc furnace should have a powerful transformer high thermal and electrical efficiency and a lining made of high-grade refractory Edneral 1979. A robust design guarantees mechanical strength for steel furnace operation and temperature control for continuous high loads in ferro-alloy operation. Design Features Of An Ac Electric Arc Furnace Ispatguru.

There are many factors to be considered in the selection of rated voltage of furnace transformer. The furnace reactance affects the required transformer capacity as well as the. There are many factors to be considered in the selection of rated voltage of furnace transformer. A robust design guarantees mechanical strength for steel furnace operation and temperature control for continuous high loads in ferro-alloy operation. During EAF operation there are varying needs of arc voltagecurrent configuration through and for this reason its necessary to have the correct choice of the secondary voltages. Functional Diagram Of An Electrical Control System For A Modern Arc Download Scientific Diagram.

An electric arc furnace should have a powerful transformer high thermal and electrical efficiency and a lining made of high-grade refractory Edneral 1979. The reactance must be taken into account when designing the transformers for a new furnace. Delta connected secondary windings are preferred and reduce the. The bath is usually conical-spherical. Electric arc furnaces transformers EAF are used to power arc furnaces for the production of steel and special ferroalloys. Electric Arc Furnace Transformer 33kv 110mva Transformer Buy Electric Arc Furnace Transformer Induction Furnace Transformer Furnace Transformer Product On Alibaba Com.

The arc forms between the charged material and the electrode the charge is heated both by current passing through the charge and by the radiant energy evolved by the arc. The reactance must be taken into account when designing the transformers for a new furnace. DC arc furnaces electrolysis scrap melting furnaces aluminum smelter graphitising furnaces. This applications which require high levels of power that also operate under very severe conditions to frequent over currents and over voltage generated by short circuits in the furnace and the operating of HV circuit-breaker. Electrical Arc Furnace Power Transformers Connections When designing arc furnace transformers due to the asymetric loading requirements of the three phases it is usually necessary to provide separate voltage regulation for each phase and therefore single-phase circuit breakers. An Algorithm For Fast Calculation Of Short Circuit Forces In High Current Busbars Of Electric Arc Furnace Transformers Based On Method Of Images Sciencedirect.

The use of a thyristor rectifier for the conversion to DC will normally reduce the requirement for on-load voltage regulation of the furnace transformer. The electric arc furnace operating cycle is called the tap-to-tap cycle and is made up of the following operations. A robust design guarantees mechanical strength for steel furnace operation and temperature control for continuous high loads in ferro-alloy operation. Design of submerged arc furnaces with particular reference to production of high-silicon alloys by TE. Frequent on and off switching high magnitude inrush currents. Submerged Arc Furnace Transformer 22000kva 110kv Single Phase Manufacturers Cost Price Scotech.

The use of a thyristor rectifier for the conversion to DC will normally reduce the requirement for on-load voltage regulation of the furnace transformer. The position 21 ratio is 30 kV1154 V. Arc Submerged Arc Ladle Induction Upto 10 MVAUpto 33kVONANOFWF Cooling A high current furnace transformer is provided by having the low-voltage windings arranged in a closed delta configuration within the transformer enclosure. An electric arc furnace should have a powerful transformer high thermal and electrical efficiency and a lining made of high-grade refractory Edneral 1979. Sized electric arc furnaces were used as a guide in the design of this prototype. Sub Merged Arc Furnace Transformers Kva Process Transformer.

The utility to the step down transforme r the arc furnace transformer and the. For tap position 15. Furnaces transformers life is affected by heavy stresses during operation. An electric arc furnace should have a powerful transformer high thermal and electrical efficiency and a lining made of high-grade refractory Edneral 1979. The mentioned transformer is designed in order to allow operation of the arcs at the desired range of arc voltages and currents. Pdf Modelling And Control Of A Three Phase Electric Arc Furnace Semantic Scholar.

Magnussen. Transformers used in electrical arc furnace installations can be very exacting. DESIGN THEORY AND CALCULATIONS. DC Arc Furnace Transformers Applications Most large DC arc furnaces are built for steel production. Arc Submerged Arc Ladle Induction Upto 10 MVAUpto 33kVONANOFWF Cooling A high current furnace transformer is provided by having the low-voltage windings arranged in a closed delta configuration within the transformer enclosure. Schematic Diagram Of A Submerged Arc Furnace Download Scientific Diagram.

For tap position 15. Recent examples of arc furnace transformer failures illustrate. Furnaces transformers life is affected by heavy stresses during operation. Furnace charging Melting Refining De-slagging Tapping Furnace turn-around Modern operations aim for a tap-to-tap time of less than 60 minutes. The techniques of the operation and the unusual loads they produce are so severe particularly on the transformer that special design requirements and later the maintenance of the units is essential. Ac Arc Furnace Transformers.

We produces transformers for all furnace applications counting long-arc steel and short-arc ferro-alloy operationA robust design ensures mechanical quality for steel furnace operation and temperature control for nonstop high loads in ferro-alloy operationArc heaters vary from acceptance heaters in that the charge fabric is specifically uncovered to an electric arc and the current within. The arc furnace where scrap materials are charged has three electrodes connected to the secondary terminals of the furnace transformer. For tap position 15. The techniques of the operation and the unusual loads they produce are so severe particularly on the transformer that special design requirements and later the maintenance of the units is essential. The innovative TDRH digital electrode regulation system provides a. Furnace Rectifier Transformers Kitashiba Electric Co Ltd.