The new Inspection Specifications addition to the Seal Design Guide includes information on. Standard-sized O-rings are readily available in the following materials. apple rubber o ring groove design.

Apple Rubber O Ring Groove Design, The O-ring inner diameter ID should also stretch approximately 5 over your groove or gland. One of the faces will be completely smooth and one will have an o-ring groove cut into it. Clearance Determine the maximum clearance present in.

Groove Design O Ring Seals Minnesota Rubber Plastics From mnrubber.com

Groove Design O Ring Seals Minnesota Rubber Plastics From mnrubber.com

PTFE rings may work for you but could be marginal. Dynamic Reciprocating O-Ring Gland Design. Standard-sized O-rings are readily available in the following materials.

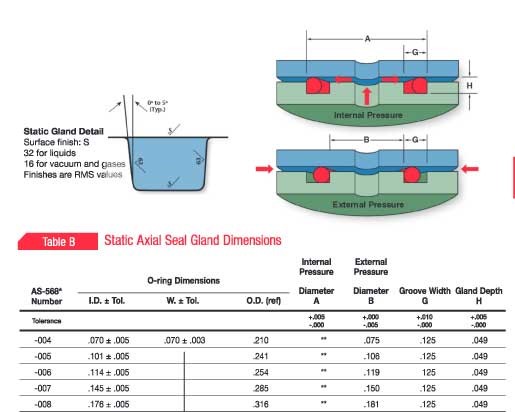

Browse design considerations and recommendations for static face seals metric o-rings static dovetail o-rings static rod-piston o-rings and dynamic rod-piston o-rings.

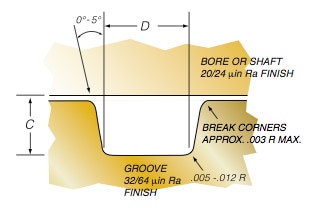

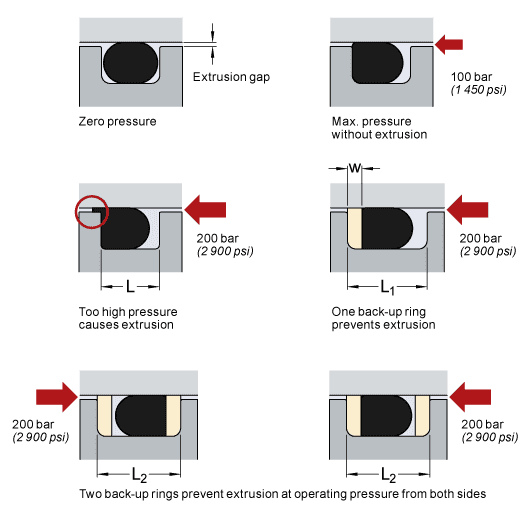

Basic Application Groove Design Reference Charts - Expert Application Engineer Support. O-ring Groove Design in 3 easy steps. The design of the groove where the o-ring sits plays a major role in how the o-ring performs its sealing role. - When using only one back-up ring be sure to install it on the low-pressure side of the O-ring. The O-ring inner diameter ID should also stretch approximately 5 over your groove or gland. Backup rings are likely needed.

Another Article :

30 per line item minimum. Also the groove width is generally less as PTFE O-rings are much less likely to roll in reciprocating applications than their elastomeric counterparts. Expert Application Engineering Assistance. The new Inspection Specifications addition to the Seal Design Guide includes information on. Choose whether you are working with existing hardware or designing new hardware. The Apple Rubber Seal Design Guide Turns 25 Official Apple Rubber Blog.

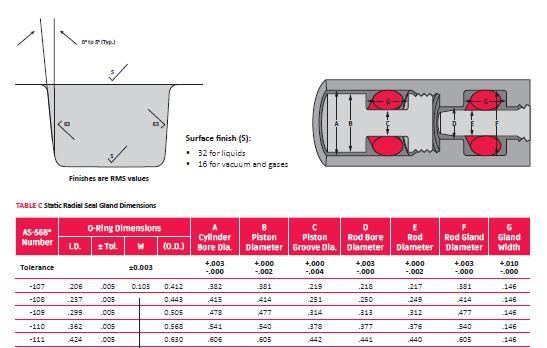

There are two types of radial designs. Based on the cross section CS of your O-ring you will choose the corresponding O-ring groove depth and O-ring groove width dimensions. Cross-section Select a Quad-Ring Brand cross-section size from the available standard sizes. Designing the parts of an application where o-rings will be applied is broadly termed o-ring groove design. The second tradeoff is that 90 durometer rings are less tolerant of a poor finish so you need to maintain the prescribed 16 rms finish on the bore and groove OD. How To Design An O Ring Groove Vizeng.

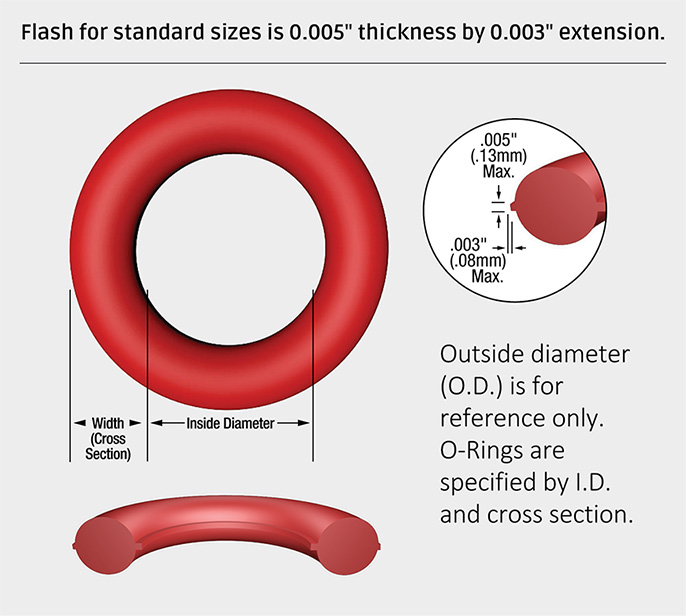

An O-ring is a circular cross-section ring molded from rubber. Review the general o-ring groove design. O-ring and gland constitute the classic O-ring seal assembly. Groove Bore Piston Rod Figure 1-2. O-ring Groove Design in 3 easy steps. Montre F1 Carbon Gmt Concept Watch Cool Watches Watch Design Watches For Men.

Review the general o-ring groove design. Grooves for PTFE O-Rings are similar to those for rubber O-Rings except that less squeeze is applied due to the relative stiffness of the material. O-ring and gland constitute the classic O-ring seal assembly. Black Nitrile Buna-N 70 or 90 Brown or Black Viton 75 Black EPDM 70 Red Silicone 70 Black Neoprene 70 and White PTFE. These type of glands are used for a variety of applications bolted flanges or removable lids. 4 Common Mistakes In Designing For An O Ring Axial Face Seal Hot Topics.

Black Nitrile Buna-N 70 or 90 Brown or Black Viton 75 Black EPDM 70 Red Silicone 70 Black Neoprene 70 and White PTFE. An o-ring is a simple and versatile ring shaped packing or sealing device. Choose whether you are working with existing hardware or designing new hardware. These type of glands are used for a variety of applications bolted flanges or removable lids. - When using only one back-up ring be sure to install it on the low-pressure side of the O-ring. Pin On Smartwatch Bands.

To minimize breakaway friction an O-Ring groove must be wide enough to allow rolling or twisting of the seal. Grooves for PTFE O-Rings are similar to those for rubber O-Rings except that less squeeze is applied due to the relative stiffness of the material. Depending on your application you can have the groove be cut in either the piston or the bore. Review the general o-ring groove design. You will find in-depth information on each of these rules and more in the new Seal Design Guide published by Apple Rubber Products. How To Save Time On Medical Rubber Part Design Hot Topics.

Grooves for PTFE O-Rings are similar to those for rubber O-Rings except that less squeeze is applied due to the relative stiffness of the material. O-rings are often referred to as piston and rod seals when used in these types of applications. O-ring groove design is a key consideration in the o-ring selection process. Black Nitrile Buna-N 70 or 90 Brown or Black Viton 75 Black EPDM 70 Red Silicone 70 Black Neoprene 70 and White PTFE. 30 per line item minimum. Groove Design O Ring Seals Minnesota Rubber Plastics.

Be it dynamic or static operation radial or axial loading vacuum or high pressure. O-ring and gland constitute the classic O-ring seal assembly. Now follow the steps below to design your own o-ring seal and o-ring groove. This is the first number that is needed. In order to seal properly the o-ring has to deform in the application by being compressed and stretched in any number of ways. 1pcs 6016 2rs 6016 Rs 80x125x22mm Rubber Sealed Deep Groove Ball Bearing Brand New Deep Rings For Men Groove.

You will find in-depth information on each of these rules and more in the new Seal Design Guide published by Apple Rubber Products. Be it dynamic or static operation radial or axial loading vacuum or high pressure. An O-ring is a circular cross-section ring molded from rubber. Having a circular cross section that functions as a seal in both static and dynamic applications by being compressed between the mating surfaces comprising the walls of the gland in which it is installed. The groove shape is very similar to that of face seals. O Rings Standard As568 Iso 3601 Apple Rubber Products.

Make sure that the material you choose will withstand the temperature of your system by. In order to seal properly the o-ring has to deform in the application by being compressed and stretched in any number of ways. O-rings are often referred to as piston and rod seals when used in these types of applications. The groove must be designed to accommodate not just the oring size but also its intended usage. Groove Bore Piston Rod Figure 1-2. Designing Axial Static O Ring Grooves To Industry Standards Grabcad Tutorials.

Choose whether you are working with existing hardware or designing new hardware. Be it dynamic or static operation radial or axial loading vacuum or high pressure. Expert Application Engineering Assistance. You will find in-depth information on each of these rules and more in the new Seal Design Guide published by Apple Rubber Products. O-ring groove design is a key consideration in the o-ring selection process. Groove Design O Ring Seals Minnesota Rubber Plastics.

Expert Application Engineering Assistance. Grooves for PTFE O-Rings are similar to those for rubber O-Rings except that less squeeze is applied due to the relative stiffness of the material. Also the groove width is generally less as PTFE O-rings are much less likely to roll in reciprocating applications than their elastomeric counterparts. In the long stroke of a reciprocating seal application this twisting action can strain and eventually tear the rubber causing a failure mode known as spiral twist. Having a circular cross section that functions as a seal in both static and dynamic applications by being compressed between the mating surfaces comprising the walls of the gland in which it is installed. O Ring Basics Apple Rubber.

An o-ring is a simple and versatile ring shaped packing or sealing device. Backup rings are likely needed. The groove must be designed to accommodate not just the oring size but also its intended usage. The new Inspection Specifications addition to the Seal Design Guide includes information on. Standard-sized O-rings are readily available in the following materials. O Rings And Back Up Rings Skf Skf.

PTFE rings may work for you but could be marginal. Having a circular cross section that functions as a seal in both static and dynamic applications by being compressed between the mating surfaces comprising the walls of the gland in which it is installed. Use a good O-ring grease like Molykote 55 or 111. There are two types of radial designs. The groove shape is very similar to that of face seals. Designing Axial Static O Ring Grooves To Industry Standards Grabcad Tutorials.

Standard and Metric Sizes. The second tradeoff is that 90 durometer rings are less tolerant of a poor finish so you need to maintain the prescribed 16 rms finish on the bore and groove OD. Also the groove width is generally less as PTFE O-rings are much less likely to roll in reciprocating applications than their elastomeric counterparts. To minimize breakaway friction an O-Ring groove must be wide enough to allow rolling or twisting of the seal. For those who are unfamiliar with O-ring design it is rec-ommended to fi rst. Groove Design O Ring Seals Minnesota Rubber Plastics.