CR stands for Compression Ratio max engine volume divided by min engine volume. If playback doesnt begin shortly try restarting your device. alpha stirling engine design calculations.

Alpha Stirling Engine Design Calculations, 3 X Diameter of Displacement Cyl. Inputs to calculate heat conduction. This paper presents the results of calculation studies of a free-piston Stirling engine.

Design And Heat Transfer Optimization Of A 1 Kw Free Piston Stirling Engine For Space Reactor Power System Sciencedirect From sciencedirect.com

Design And Heat Transfer Optimization Of A 1 Kw Free Piston Stirling Engine For Space Reactor Power System Sciencedirect From sciencedirect.com

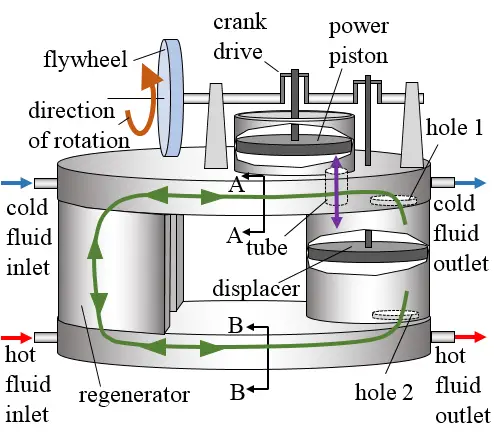

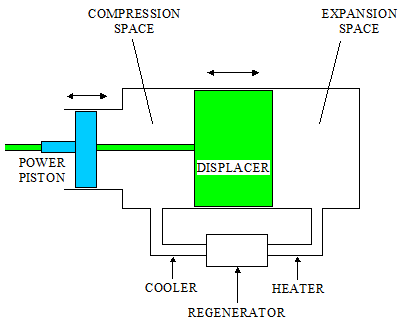

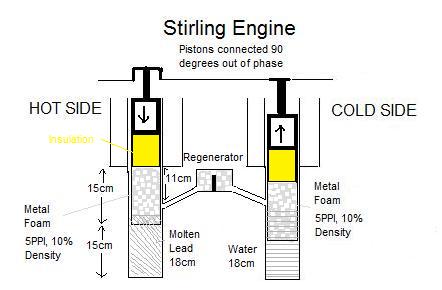

Some of these use steam as a gaseous working fluid. Its schematic diagram is shown in Figure 7. A Stirling engine is a power machines with 4 external combustion that operates over a closed internal gas cycle involving cyclic compression as well as the expansion of the working fluid at different temperature le-.

After finalizing the dimensions of each and every component of the engine A CAD model of a alpha configuration of Stirling Engine was developed on CREO Software.

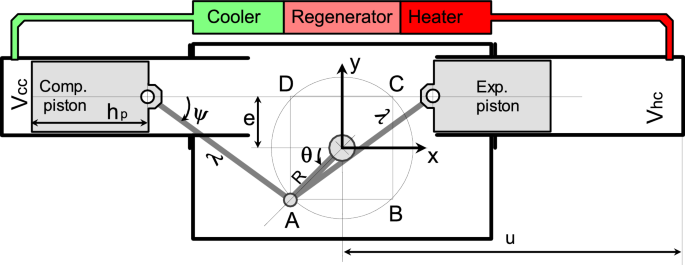

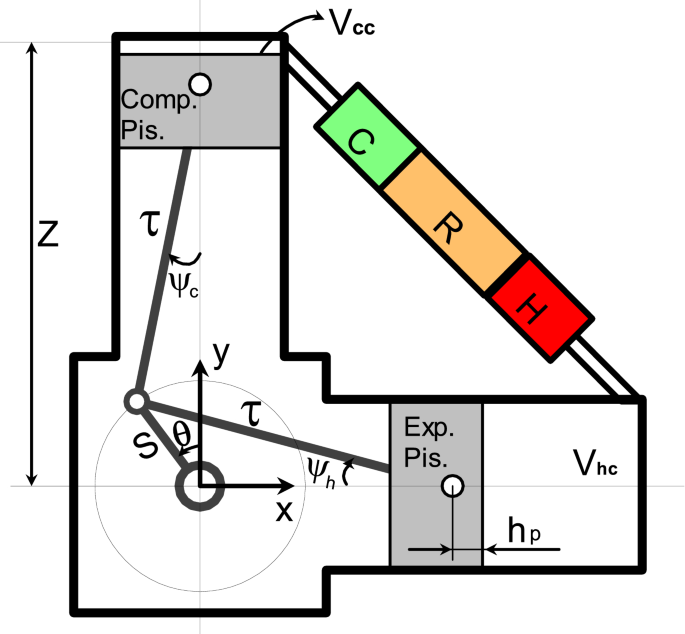

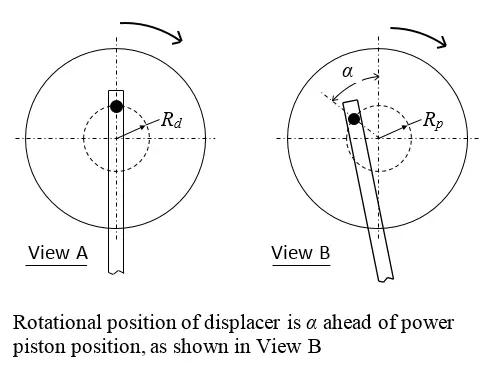

A Stirling engine is a power machines with 4 external combustion that operates over a closed internal gas cycle involving cyclic compression as well as the expansion of the working fluid at different temperature le-. The objective of this study is to develop accurate thermodynamic model for the α-type Stirling engines with Ross Yoke drive mechanism. This crank angle is defined as x0 when the expansion piston is located the most top. 1st Variable Diameter of Displacement Cyl. P T π N30 or approximately T N 01047 RPM 140 Torque arm 200 mm 02 m Net scale reading maximum. 3 X Diameter of Displacement Cyl.

Another Article :

Solar Stirling Engine Systems for Energy Independence PDF. The Stirling engine 3 was invented in 1816 by Robert Stirling. Non-dimensional analysis uses a variet y of ratios including temperature pressure and volume to analyse a. However there are many types of heat engines or external combustion engines designed by many other inventors. Teachers and a full curriculum are needed for the school setting that we will design to set up our lesson plan type project. Basic Components Of Beale Free Piston Stirling Engine 3 Download Scientific Diagram.

1st Variable Diameter of Displacement Cyl. Additionally useful work produced can be calculated with the following formula. 222 Calculation and Design 2221 Solar Calculations In order to find the total radiation received in a day radiation received in Kathmandu. This engine design has been used in a lot of experiments including Solar Power experiments for green energy. The Stirling engine 3 was invented in 1816 by Robert Stirling. Low Temperature Stirling Engine.

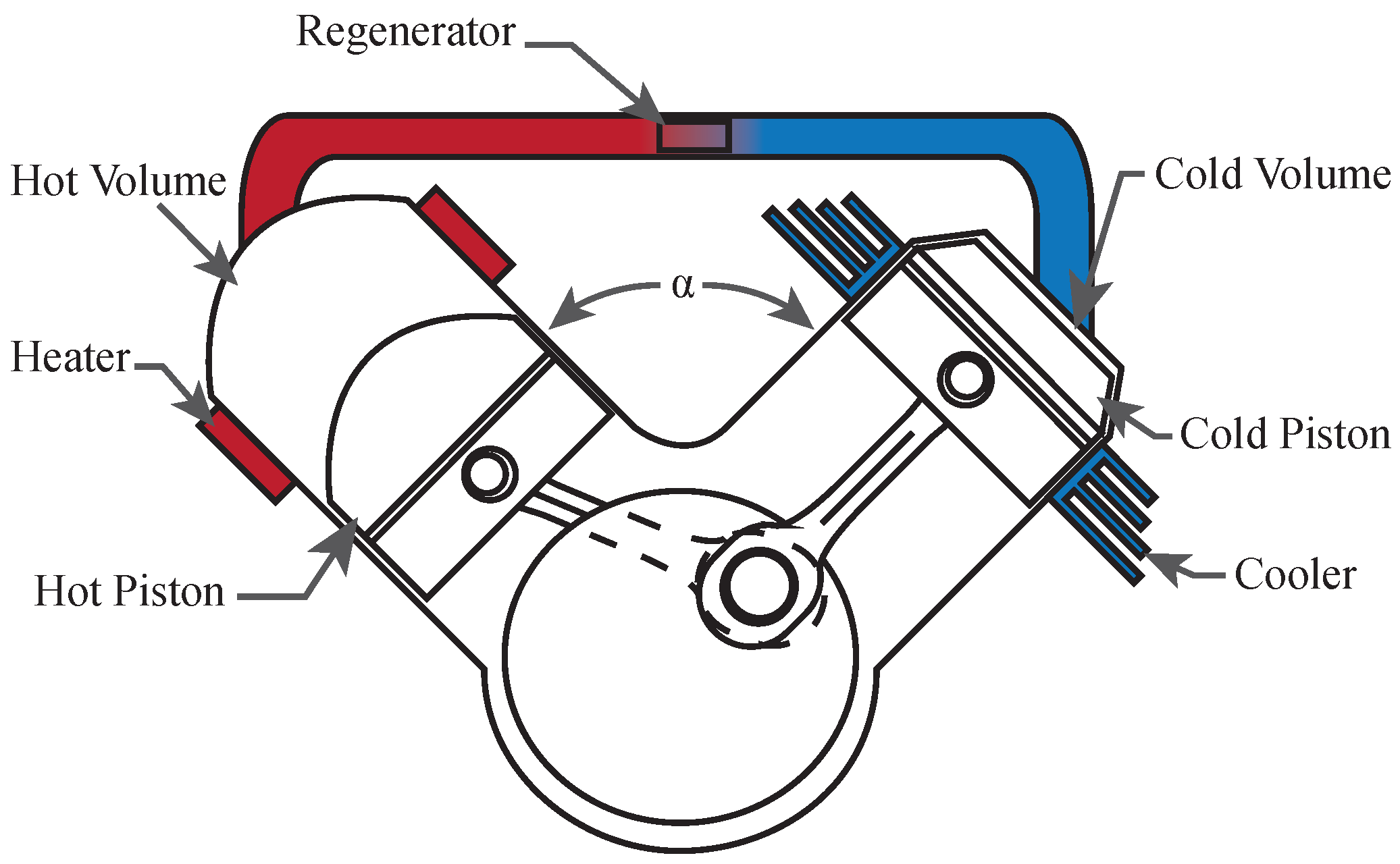

This engine design has been used in a lot of experiments including Solar Power experiments for green energy. Angle between the two cylinders. The calculations allow you to find the total volume of the gas the mass of the gas and the pressure of the gas. This engine design has been used in a lot of experiments including Solar Power experiments for green energy. Design and Optimization of a 1 kW Stirling Engine Garrett Tyler Rinker grinkermixwvuedu Follow this and additional works at. Low Temperature Stirling Engine.

Generating between 200-500 watts of electricity. This crank angle is defined as x0 when the expansion piston is located the most top. Often 0 or 90 degrees. Alpha Stirling Engine - YouTube. The momental volumes is described with a crank angle - x. Mechanical Configuration And Thermodynamic Analysis Of An Alpha Type Stirling Engine With Crank Shifted Driving Mechanism Springerlink.

Angle between the two cylinders. 1 Alpha-type Stirling Engine The volumes of the expansion- and compression cylinder at a given crank angle are determined at first. Non-dimensional analysis uses a variet y of ratios including temperature pressure and volume to analyse a. After finalizing the dimensions of each and every component of the engine A CAD model of a alpha configuration of Stirling Engine was developed on CREO Software. 12cm gap in hot cap expansion cylinder diameter-displacer diam2. Investigation And Development Of Modified Ross Yoke Mechanism On Alpha Parallel Cylinder Stirling Engine Springerlink.

Inputs to calculate heat conduction. These include amongst oth-ers operating pr essure dimensional aspects such as bore to maximum piston displacement ratio heat exchanger and regenerator design and void volume minimisation. The design calculation are done with as per standards and the experimental prototype striling engine power out is identified. CR stands for Compression Ratio max engine volume divided by min engine volume. The objective of this study is to develop accurate thermodynamic model for the α-type Stirling engines with Ross Yoke drive mechanism. Layout Of The Prototype Alpha Type Stirling Engine Layout Of The Download Scientific Diagram.

Heat engines are typically accepted as Stirling engines. The developed model aims to calculate and evaluate the optimal design parameters to obtain maximum power and efficiency. Often 0 or 90 degrees. There are three basic types of Stirling heat engines. The irreversibility of a stirling engine is considered with the heat transfer following Newtons law. Stirling Engine.

12cm gap in hot cap expansion cylinder diameter-displacer diam2. CR stands for Compression Ratio max engine volume divided by min engine volume. The objective of this study is to develop accurate thermodynamic model for the α-type Stirling engines with Ross Yoke drive mechanism. Heat engines are typically accepted as Stirling engines. Several designs were studied before settling on an alpha type configuration based around a two-cylinder air compressor. Mechanical Configuration And Thermodynamic Analysis Of An Alpha Type Stirling Engine With Crank Shifted Driving Mechanism Springerlink.

These include amongst oth-ers operating pr essure dimensional aspects such as bore to maximum piston displacement ratio heat exchanger and regenerator design and void volume minimisation. Stirling Design Calculations for Alpha Type based on certain Theories. 1 Alpha-type Stirling Engine The volumes of the expansion- and compression cylinder at a given crank angle are determined at first. Generating between 200-500 watts of electricity. This crank angle is defined as x0 when the expansion piston is located the most top position top dead point. Energies Free Full Text Efficiency Reduction In Stirling Engines Resulting From Sinusoidal Motion Html.

The irreversibility of a stirling engine is considered with the heat transfer following Newtons law. Of Displacement Cyl54 mm. 12cm gap in hot cap expansion cylinder diameter-displacer diam2. They were done using our proposed method of calculation which combines adiabatic calculation of the engines thermodynamic parameters with dynamics of the displacer and working piston oscillations. One of the means of energy conversions is Stirling engine. Stirling Cycle An Overview Sciencedirect Topics.

We decided to manufacture a Stirling engine having 49cc displacement capacity and accordingly the LD ratio was calculated for the cylinders and the piston. Heat engines are typically accepted as Stirling engines. 1st Variable Diameter of Displacement Cyl. B Length of Heating Zone of Displacement Cyl2 X Diam. Still considered one of the best methods of analysis for Stirling engine design. Investigation And Development Of Modified Ross Yoke Mechanism On Alpha Parallel Cylinder Stirling Engine Springerlink.

DESIGN OF STIRLING ENGINE. 1 Alpha-type Stirling Engine The volumes of the expansion- and compression cylinder at a given crank angle are determined at first. DESIGN OF STIRLING ENGINE. Stirling Engine Renaissance in 21st Century. It has a higher efficiency than the other two types of engines so it is typically used more often. Basic Configuration For The Double Acting Stirling Engine With Four Download Scientific Diagram.

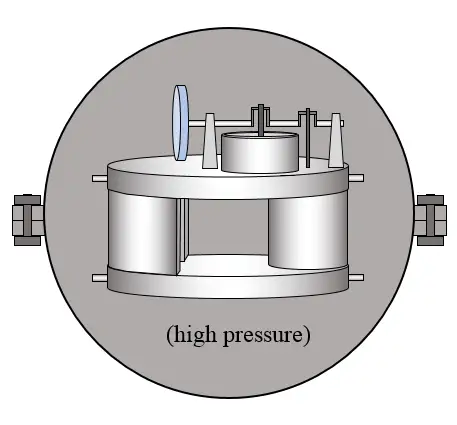

ALPHA-TYPE STIRLING ENGINE Figure 1 shows the calculation model of Alpha-type Stirling engine. SCHMIDT THEORY FOR STIRLING ENGINES Fig. Several designs were studied before settling on an alpha type configuration based around a two-cylinder air compressor. The volumes of the expansion- and compression cylinder at a given crank angle are determined at first. The present work explained the design and fabrication of the stirling engine. Stirling Engine Design High Pressure 40atm High Temperature 600 Degrees Celsius Stirling Engine Using Two Petrol Motors.

The momental volumes is described with a crank angle - x. Still considered one of the best methods of analysis for Stirling engine design. Non-dimensional analysis uses a variet y of ratios including temperature pressure and volume to analyse a. Gamma type stirling engine configuration. The design calculation are done with as per standards and the experimental prototype striling engine power out is identified. Low Temperature Stirling Engine.

Teachers and a full curriculum are needed for the school setting that we will design to set up our lesson plan type project. 3 X Diameter of Displacement Cyl. DESIGN OF STIRLING ENGINE. Inputs to calculate heat conduction. Still considered one of the best methods of analysis for Stirling engine design. Genoa Stirling Engine Scheme 27 28 Download Scientific Diagram.