The basic lifting beam is shown in Fig. Lifting beam and redesigned lifting lugs for the 241AZ01A decant pump. aisc lifting beam design.

Aisc Lifting Beam Design, Most erectors and riggers accumulate an assortment of lifting beams during the course of time. Lifting beams are designed to take bending loads. Design of Beams and Other Flexural Members AISC LRFD 3rd Edition 2001 Jose-Miguel Albaine MS PE.

Designing A Spreader Beam For Lifting Thenavalarch From thenavalarch.com

Designing A Spreader Beam For Lifting Thenavalarch From thenavalarch.com

Lifting beams also known as spreader beams are used to assist in the hoisting process. A simple lifting beam. Lifting beams on the other hand are designed to take bending loads.

Some common profiles are shown in Fig.

Some common profiles are shown in Fig. Design calculation of a monorail beam is only a portion of a well-planned overhead material handling system. Find reactions from the. Transform line load on the beam into a point load in order to determine the reactions from the supports. A simple lifting beam is shown below. Typically when applying the AISC Specification I would go back to the Pincus and Duerr research to.

Another Article :

If youd like to validate this calculator use our closed-form beam calculator to compare results. The basic lifting beam is shown in Fig. LIFTING LUG ANALYSIS ASD Per AISC 13th Edition ASD Manual ASME BTH-1-2008 and Design and Construction of Lifting Beams by David T. We can see that it has a lifting eye at its top in the middle while the eyes below are used to connect the slings to the lifted object. Industrial Buildings-Roofs to Anchor Rods 2nd Edition. Design And Buckling Strength Evaluation Of A Lifting Beam For 350 Tonnes Through Fea Semantic Scholar.

ADesign and Construction of Lifting Beams - David T. Similar to AISC 9th Ed. Design and Construction of Lifting Beams DAVID T. Lug Yield StrengthFy 341ksi 235Mpa Lug Ultimate StrengthFu 580ksi 400Mpa Edge Distance a 256in 65mm Edge Distance e 118in 30mm Lug Width b 610in 155mm. 74 Specifications for Top Running Under Running Single Girder Electric Traveling. Design And Construction Of Lifting Beams Semantic Scholar.

Accounting for the safety factors for lifting lug design using the AISC Specification has been done in a much more ad hoc fashion. CMAA 70-04 Specifications for Top Running Bridge and Gantry Type Multiple Girder Electric Overhead Traveling Cranes. Most erectors and riggers accumulate an assortment of lifting beams during the course of time. 53134 Structural Design II My the maximum moment that brings the beam to the point of yielding For plastic analysis the bending stress everywhere in the section is Fy the plastic moment is a F Z A M F p y y 2 Mp plastic moment A total cross-sectional area a distance between the resultant tension and compression forces on the cross-section a A. Aisc Design And Construction Of Lifting Beams Posted on August 25 2020 by Sandra Demo s graitec lifting lug corrugated i beams aisc lifting lug ysis of offs platforms lifting. Design And Construction Of Lifting Beams Semantic Scholar.

Lifting beams can have adjustable lifting points which can be moved along the beam to suit the particular load. Find reactions from the. Ricker originally published in American Institute of Steel Construction AISC - Design Journal 4th Quarter 1991. Design and Construction of Lifting Beams Engineering Journal American Institute of Steel Construction Vol. Design and Construction of Lifting Beams. Pdf Design And Construction Of Lifting Beams Chan Myae Academia Edu.

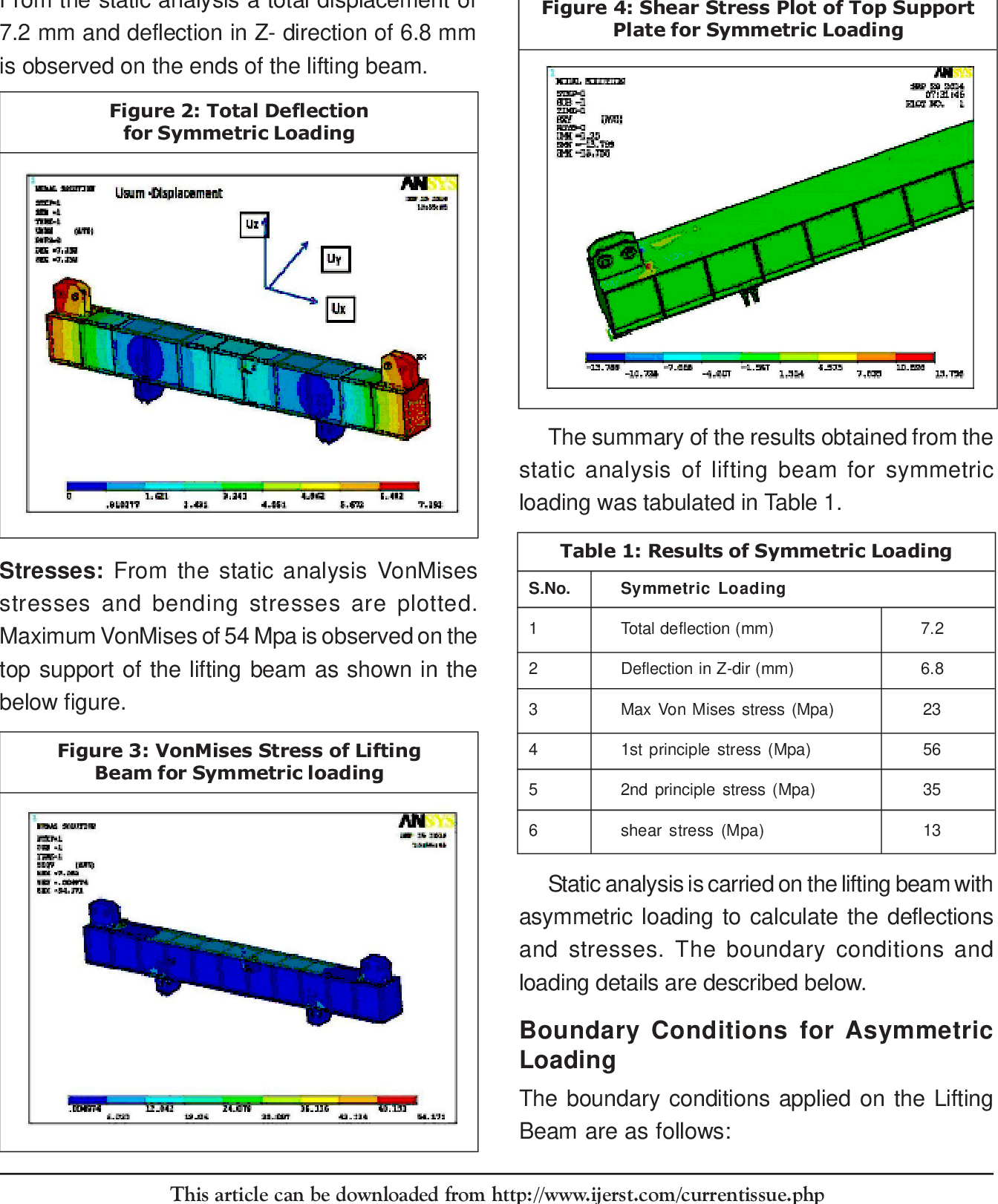

AISC Design Guide 7. Design calculation of a monorail beam is only a portion of a well-planned overhead material handling system. CISC Guide for the Design of Crane-Supporting Steel Structures 2nd Edition. The procedure presented for the design of a monorail beam is primarily based on the Crane Manufacturers Association of America CMAA Specification No. The design is also validated by performing finite element analysis using Ansys software3d model is. Designing A Spreader Beam For Lifting Thenavalarch.

Calculate load based on maximum moment. If you need full design checks via AISC 360 NDS ASD and LRFD for steel or wood beam design and you want to design your next. The basic lifting beam is shown in Fig. This design is in accordance with Standard Architectural-Civil Design Criteria Design Loads for Facilites DOE-RL 1989 and is safety class three. Typically when applying the AISC Specification I would go back to the Pincus and Duerr research to. Design And Construction Of Lifting Beams Semantic Scholar.

Lifting beams also known as spreader beams are used to assist in the hoisting process. I believe OSHA will reference ASME B3020. ADesign and Construction of Lifting Beams - David T. Compare Lb to Lp and Lr and determine which equation for Mn or Mcr to be used. The procedure presented for the design of a monorail beam is primarily based on the Crane Manufacturers Association of America CMAA Specification No. Designing A Spreader Beam For Lifting Thenavalarch.

Design and Construction of Lifting Beams. Lifting beam and redesigned lifting lugs for the 241AZ01A decant pump. Here t he lifting beam is designed for lifting of a material of 350 Tonnes. Most erectors and riggers accumulate an assortment of lifting beams during the course of time. CMAA 70-04 Specifications for Top Running Bridge and Gantry Type Multiple Girder Electric Overhead Traveling Cranes. Pin On Cae.

If we resolve the forces we can immediately see that the lifting beam will be primarily under bending stress see figure 2. Accounting for the safety factors for lifting lug design using the AISC Specification has been done in a much more ad hoc fashion. Some common profiles are shown in Fig. CMAA 70-04 Specifications for Top Running Bridge and Gantry Type Multiple Girder Electric Overhead Traveling Cranes. If youd like to validate this calculator use our closed-form beam calculator to compare results. Stresses When Lifting A Beam Mechanical Engineering General Discussion Eng Tips.

Lifting beams also known as spreader beams are used to assist in the hoisting process. Find reactions from the. ASME BTH-1 explicitly addresses the issues involved with the greatly oversized holes common in lifting lugs. Similar to AISC 9th Ed. Design and Construction of Lifting Beams Engineering Journal American Institute of Steel Construction Vol. Cb Value For Crane Rail Beam Simply Supported By Hangers Attached To Top Flange Only Structural Engineering General Discussion Eng Tips.

Some common profiles are shown in Fig. Bending Stresses and Plastic Moment The stress distribution for a linear elastic material considering small deformations is as shown on Figure No. If you need full design checks via AISC 360 NDS ASD and LRFD for steel or wood beam design and you want to design your next. Determine the beam load equation for maximum moment in the beam. There are two basic approaches to this. Design And Construction Of Lifting Beams Semantic Scholar.

Aisc Design And Construction Of Lifting Beams Posted on August 25 2020 by Sandra Demo s graitec lifting lug corrugated i beams aisc lifting lug ysis of offs platforms lifting. Lifting beam and redesigned lifting lugs for the 241AZ01A decant pump. CMAA 70-04 Specifications for Top Running Bridge and Gantry Type Multiple Girder Electric Overhead Traveling Cranes. ASME BTH-1 explicitly addresses the issues involved with the greatly oversized holes common in lifting lugs. Here t he lifting beam is designed for lifting of a material of 350 Tonnes. Design And Construction Of Lifting Beams Semantic Scholar.

We can see that it has a lifting eye at its top in the middle while the eyes below are used to connect the slings to the lifted object. Lifting beams can have adjustable lifting points which can be moved along the beam to suit the particular load. ASD with greater safety factors. The procedure presented for the design of a monorail beam is primarily based on the Crane Manufacturers Association of America CMAA Specification No. We can see that it has a lifting eye at its top in the middle while the eyes below are used to connect the slings to the lifted object. Bolted Moment Connection Spreadsheet In 2021 In This Moment Spreadsheet Connection.

ADesign and Construction of Lifting Beams - David T. Bending Stresses and Plastic Moment The stress distribution for a linear elastic material considering small deformations is as shown on Figure No. I believe OSHA will reference ASME B3020. A simple lifting beam is shown below. DesignEvalution of Overhead Lifting Lugs Page 7 1. Designing A Spreader Beam For Lifting Thenavalarch.

Most erectors and riggers accumulate an assortment of lifting beams during the course of time. Lifting beams also known as spreader beams are used to assist in the hoisting process. Lifting beams also known as spreader beams are used to assist in the hoisting process. AISC properties table 3-6 3. Tearing Tension Capacity of Lifting Lug Ricker pg 152. Designing A Spreader Beam For Lifting Thenavalarch.