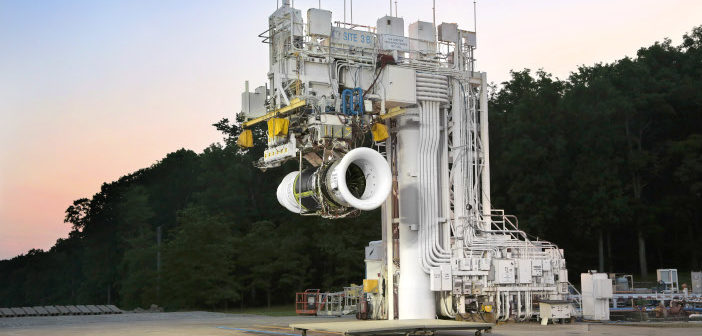

Atec Test Cell at Rolls-Royce. Calspan Aerosystems installed the first 10- x 10-meter cell for Korean Air in the 1980s. aircraft engine test cell design.

Aircraft Engine Test Cell Design, Our Design Services includes a 3D virtual model of your new test cell prior to construction saving you time and money. AIRCRAFT ENGINE TEST STANDS Backed by fifly years of experience in aerospace engine testing the Kahn Series 505 Engine Test Stands otfer a cost-effective flexible means for achieving high iest cell utilization and quick engine turnaround times. In a product as sophisticated as a test cell there are no off-the-shelf units.

Test Services Ge Aviation From geaviation.com

Test Services Ge Aviation From geaviation.com

1-5 TELEPHONE AND OTHER COMMUNICATION SYSTEMS. The test cell for aircraft jet engine is the equipment in which performance checks are conducted after maintenance of an engine and checks the operating condition of each section adjustment of each part before loading to the aircraft etc by a trial run of the engine. View this quick video that illustrates a facility with 2 Tandem Engine Dynamometer test cells control room and indoor and outdoor facility support systems.

AIRCRAFT ENGINE TEST STANDS Backed by fifly years of experience in aerospace engine testing the Kahn Series 505 Engine Test Stands otfer a cost-effective flexible means for achieving high iest cell utilization and quick engine turnaround times.

Design reference for aircraft engine test cell structure Design reference for aircraft engine test cell structure Engr1888 Structural OP 27 Jul 17 0040. The AC also provides guidance on conducting evaluating. However the test cell subjects the engine to realistic aeroelastic loadings a prime concern. CEL is a world leader in test equipment for aircraft engines turboprops helicopters business and airline jets as well as APUs Auxilliary Power Units and industrial applications. 1-5 TELEPHONE AND OTHER COMMUNICATION SYSTEMS. Our Design Services includes a 3D virtual model of your new test cell prior to construction saving you time and money.

Another Article :

Contact us for details and to ask for a price quote. Hope someone can shed me some lights. 330 4 72 14 69 00. 111 This standard establishes the minimum fire safety practices regarding location construction services utilities fire protection operation and maintenance of aircraft engine test facilities. Calspan Aerosystems installed the first 10- x 10-meter cell for Korean Air in the 1980s. F 16 Jet Engine Test At Full Afterburner In The Hush House Youtube.

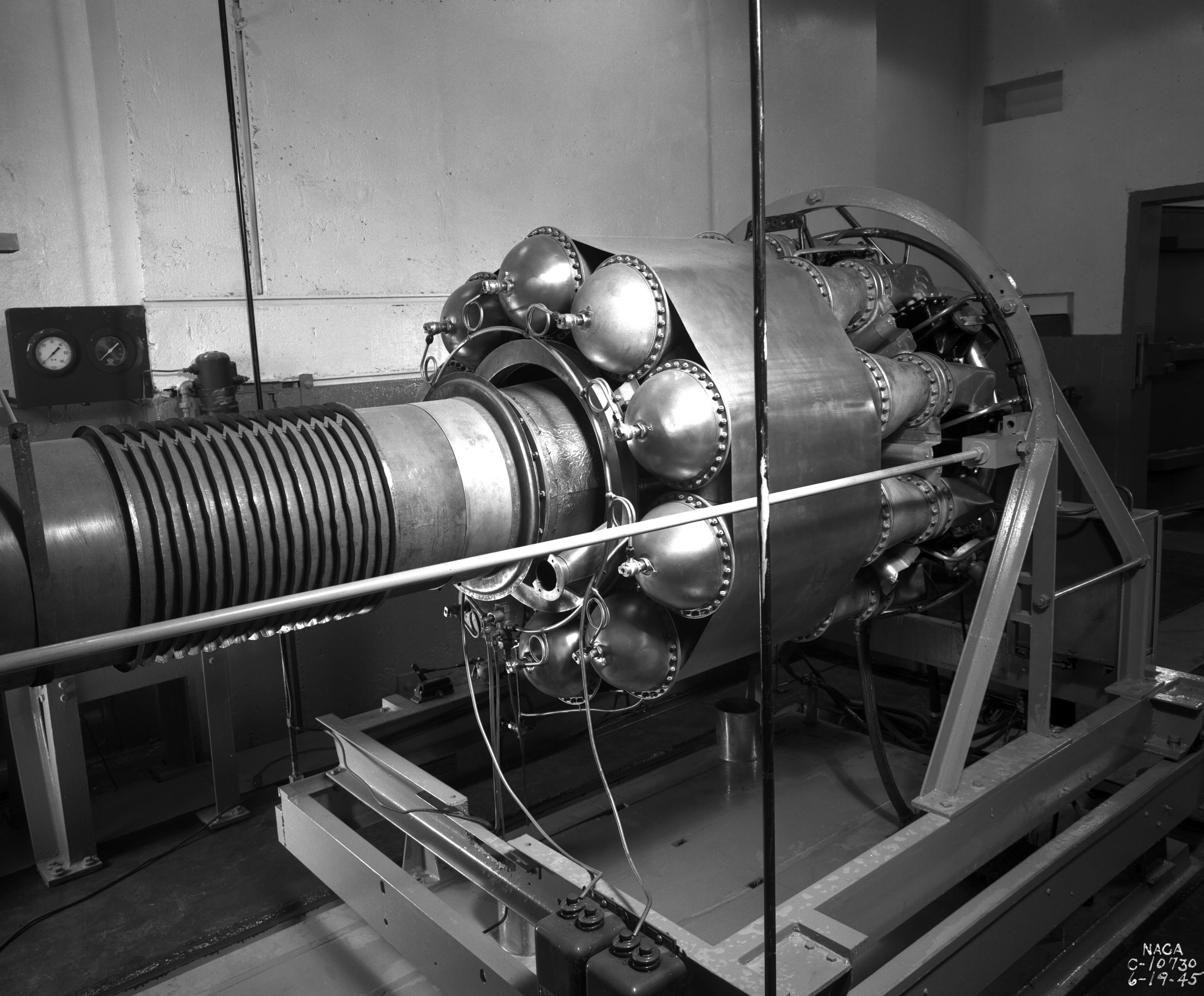

Like all advisory material this AC is not in itself mandatory and does not constitute a regulation. Such protection should also be extended to the hood and duct of the exhaust system. The facility often offered as a product to automotive OEMs allows engine operation in different operating regimes and offers measurement of several physical variables associated with the engine operation. The AC also provides guidance on conducting evaluating and maintaining test cell correlation. For additional information or assistance contact Taylor today. Early Jet Engines Glenn Research Center Nasa.

Most of these are purely mechanical and accomplished before the engine enters the cell. Korean Air was so satisfied with Calspan ASE Sales and Service that it decided to purchase the larger test cell from Calspan ASE. Based in Canada at Longueuil Quebec and with facilities in Europe and the USA our experience is. Like all advisory material this AC is not in itself mandatory and does not constitute a regulation. Development test bed III MTU Aero Engines Munich Upgrade of test bed for testing of the GP7000 MTU concept and management for. Test Services Ge Aviation.

Aircraft engine testing and Base operations have an impact on the type of construction to be used. Based in Canada at Longueuil Quebec and with facilities in Europe and the USA our experience is. However the test cell subjects the engine to realistic aeroelastic loadings a prime concern. Aerotest provides expert capabilities in developing concepts and detail designs for manufacture project management and installation to commissioning and acceptance of Aero Engine Aero Engine Accessories and Component related Test Cell facilities test equipment Ground Support equipment and support services. Currently the largest is owned and run by Delta Air Lines in Atlanta USA and is 146m high 48ft in size with inlet and exhaust sections which measure 66ft 20m and 78ft 24m. Jet Engine Test Cell Meridian Projects Burns Mcdonnell.

Inlet and exhaust duct Test cell structure and aerodynamic modifications Engine transportation system Thrust measurement system Air inlet heater MTU design Data acquisition system. For test cells used for in-service acceptance testing of turbofan and turbojet engines. Aircraft engine testing and Base operations have an impact on the type of construction to be used. However the test cell subjects the engine to realistic aeroelastic loadings a prime concern. Our test cell design team uses the latest in 3D modeling to address Aerodynamics with modern software for FEA CFD Aero Acoustics Noise Control DAS Networks thermal analysis structural and fatigue issues and liquid flow sizing to ensure that our systems meet the structural and dynamic requirements of customer and industry standards. Safran Test Cells.

Like all advisory material this AC is not in itself mandatory and does not constitute a regulation. 113 This standard does not apply to engines and engine accessories or to engine test facilities where fuels other than hydrocarbon fuels. 112 These facilities include test cells and test stands. A sophisticated engine test stand houses several sensors or transducers data acquisition features and. The new Rolls-Royce engine test centre will house the largest engine-test cell in the world. Turboshaft Engine Test Cells Atec.

There are always engine-vibration limits that must be verified during the engines production acceptance testing design assurance and diagnostic testing. Instead of sprinkler protection you could evaluate a dry chemical or carbon dioxide automatic extinguishing system or even a halon system the latter being is used in data processing rooms. Based in Canada at Longueuil Quebec and with facilities in Europe and the USA our experience is. Inlet and exhaust duct Test cell structure and aerodynamic modifications Engine transportation system Thrust measurement system Air inlet heater MTU design Data acquisition system. The AC also provides guidance on conducting evaluating. Jet Engine Test Cell Meridian Projects Burns Mcdonnell.

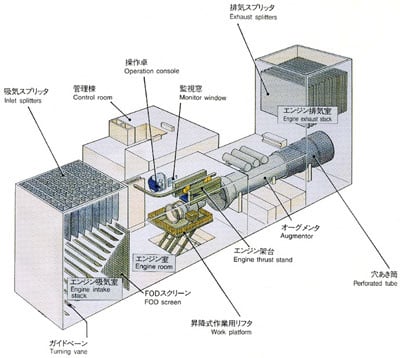

The basic design is planned to be as useful and adaptable as possible. View this quick video that illustrates a facility with 2 Tandem Engine Dynamometer test cells control room and indoor and outdoor facility support systems. The U configuration turbofan test cell is comprises a 22-meter-high intake stack a 37-meter-long 13-meter-square cross-section test cell chamber a 26-meter-long augmenter section and a 26-meter-high exhaust stack all of which are heavy and thick reinforced concrete construction. Like all advisory material this AC is not in itself mandatory and does not constitute a regulation. The test cell for aircraft jet engine is the equipment in which performance checks are conducted after maintenance of an engine and checks the operating condition of each section adjustment of each part before loading to the aircraft etc by a trial run of the engine. Future Proofing Next Generation Aircraft Engine Testing Aerospace Testing International.

The important elements of this system include the inductionexhaust system to. This AC discusses the effects of the design operation and modification of a test cell and engine test hardware on engine performance. 330 4 72 14 69 00. 112 These facilities include test cells and test stands. This AC discusses the effects of the design operation and modification of a test cell and engine test hardware on engine performance. Safran Test Cells.

Based in Canada at Longueuil Quebec and with facilities in Europe and the USA our experience is. AIRCRAFT ENGINE TEST STANDS Backed by fifly years of experience in aerospace engine testing the Kahn Series 505 Engine Test Stands otfer a cost-effective flexible means for achieving high iest cell utilization and quick engine turnaround times. Most of these are purely mechanical and accomplished before the engine enters the cell. The AC also provides guidance on conducting evaluating. Based in Canada at Longueuil Quebec and with facilities in Europe and the USA our experience is. Turboshaft Engine Test Cells Atec.

1-5 TELEPHONE AND OTHER COMMUNICATION SYSTEMS. Instead of sprinkler protection you could evaluate a dry chemical or carbon dioxide automatic extinguishing system or even a halon system the latter being is used in data processing rooms. CEL is a world leader in test equipment for aircraft engines turboprops helicopters business and airline jets as well as APUs Auxilliary Power Units and industrial applications. Inlet and exhaust duct Test cell structure and aerodynamic modifications Engine transportation system Thrust measurement system Air inlet heater MTU design Data acquisition system. Our test cell design team uses the latest in 3D modeling to address Aerodynamics with modern software for FEA CFD Aero Acoustics Noise Control DAS Networks thermal analysis structural and fatigue issues and liquid flow sizing to ensure that our systems meet the structural and dynamic requirements of customer and industry standards. Mitsubishi Heavy Industries Ltd Global Website Jet Engine Test Cell.

Aerotest provides expert capabilities in developing concepts and detail designs for manufacture project management and installation to commissioning and acceptance of Aero Engine Aero Engine Accessories and Component related Test Cell facilities test equipment Ground Support equipment and support services. View this quick video that illustrates a facility with 2 Tandem Engine Dynamometer test cells control room and indoor and outdoor facility support systems. However the test cell subjects the engine to realistic aeroelastic loadings a prime concern. For additional information or assistance contact Taylor today. In a product as sophisticated as a test cell there are no off-the-shelf units. Test Services Ge Aviation.

This AC discusses the effects of the design operation and modification of a test cell and engine test hardware on engine performance. The test cell for aircraft jet engine is the equipment in which performance checks are conducted after maintenance of an engine and checks the operating condition of each section adjustment of each part before loading to the aircraft etc by a trial run of the engine. This 14- x 14-meter test cell is the largest MRO facility in Asia. The basic design is planned to be as useful and adaptable as possible. View this quick video that illustrates a facility with 2 Tandem Engine Dynamometer test cells control room and indoor and outdoor facility support systems. How Is A Jet Engine Tested Airline Ratings.

Inlet and exhaust duct Test cell structure and aerodynamic modifications Engine transportation system Thrust measurement system Air inlet heater MTU design Data acquisition system. Engine test cells other than aircraft. The AC also provides guidance on conducting evaluating and maintaining test cell correlation. Atec Test Cell at Rolls-Royce. Hope someone can shed me some lights. Test Services Ge Aviation.

The facility often offered as a product to automotive OEMs allows engine operation in different operating regimes and offers measurement of several physical variables associated with the engine operation. Our test cell design team uses the latest in 3D modeling to address Aerodynamics with modern software for FEA CFD Aero Acoustics Noise Control DAS Networks thermal analysis structural and fatigue issues and liquid flow sizing to ensure that our systems meet the structural and dynamic requirements of customer and industry standards. The basic design is planned to be as useful and adaptable as possible. Coordinate the communications requirements with the activity. Inlet and exhaust duct Test cell structure and aerodynamic modifications Engine transportation system Thrust measurement system Air inlet heater MTU design Data acquisition system. Mitsubishi Heavy Industries Ltd Global Website Jet Engine Test Cell.