AHU Prefilter Final filter 21 Positioning of filters 31. 125 126 Temperature relative humidity and ventilation should be appropriate and should not 127 adversely affect the quality of pharmaceutical products during their manufacture and storage. ahu design in pharma.

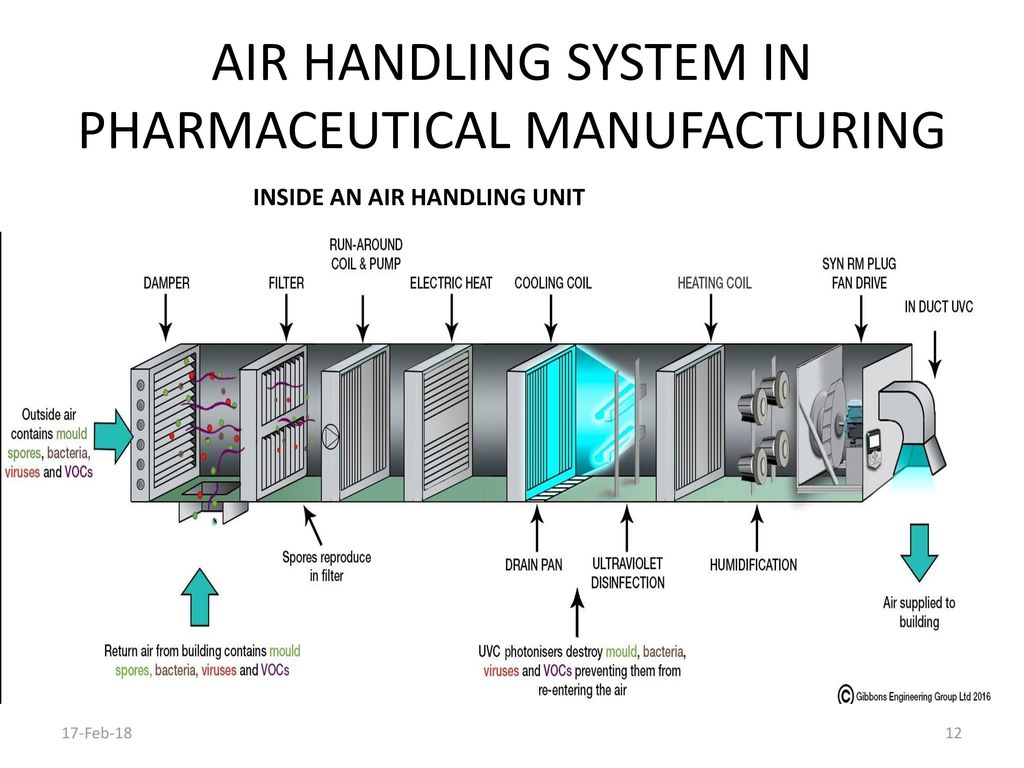

Ahu Design In Pharma, As close as possible to the point where the dust is generated should be employed. Heating Ventilation and Air Conditioning is a system that is used to control the air temperature by controlling the air filtration and the moisture in the air. Our AHU design process.

For example referring to the following figure XX measured for span RS XX is measured for span PQ. An air handler or air handling unit often abbreviated to AHU is a device used to condition and circulate air as part of a heating ventilating and air-conditioning HVAC system. This is the classification we usually specify for our AHU.

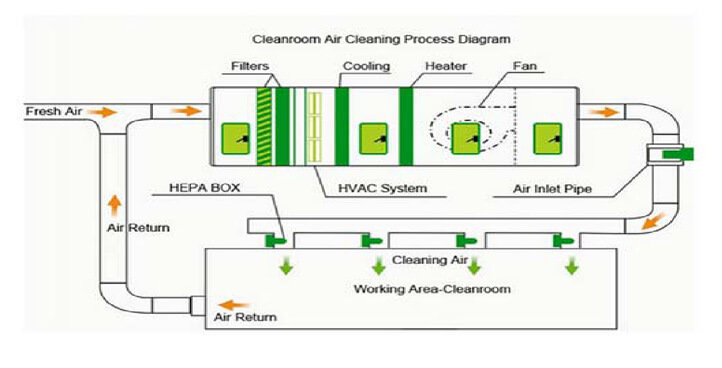

Air re-circulation The filtered air entering a production room can be 100 exhausted or a proportion re-circulated GMP aspect economical reasons 32.

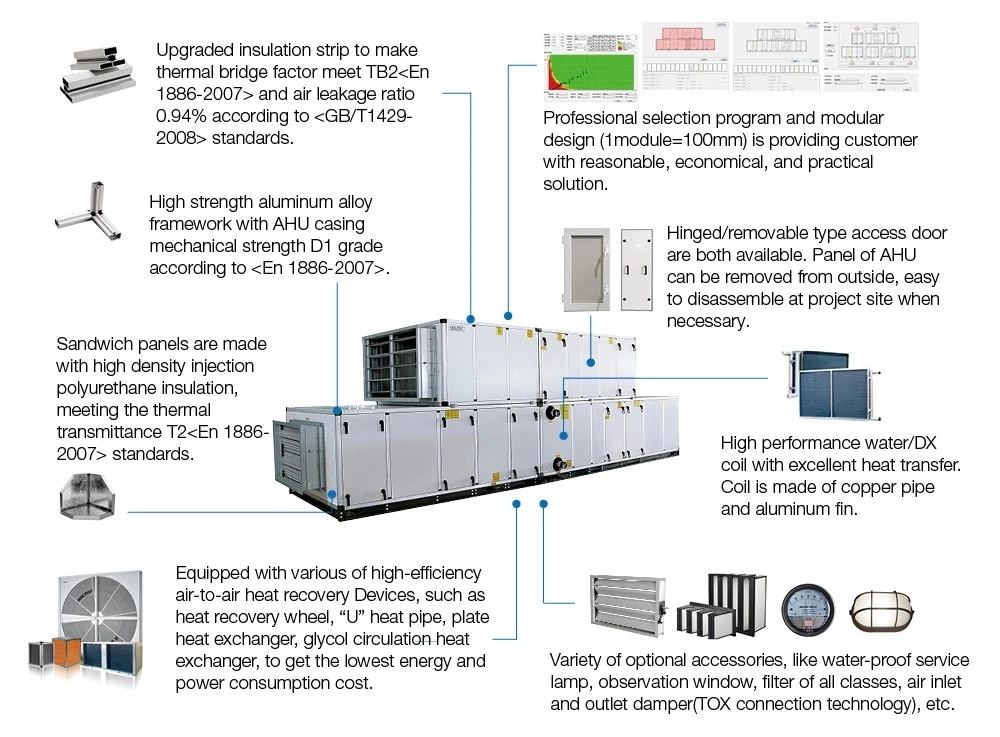

These aspects the design of the HVAC system123 should be considered at the initial design stage 124 of a pharmaceutical manufacturing plant. Dust control in Pharma Company in measure challenge Wherever possible dust or vapour contamination should be removed at source. Fan coils perimeter radiation unit ventilators unit heaters etc. For example referring to the following figure XX measured for span RS XX is measured for span PQ. AHU is of recirculated type and made from double skin panels filled with PUF insulation density of 48 kgm3 and assembled as a closed box with Aluminum profiles. An air handler or air handling unit often abbreviated to AHU is a device used to condition and circulate air as part of a heating ventilating and air-conditioning HVAC system.

Another Article :

As close as possible to the point where the dust is generated should be employed. Huber Ranner offer the AHU you need. HVAC systems Heating Ventilation and Air Conditioning systems are the integral part of environmental control system design. Air Handling Unit AHU is a device used to condition and circulate air as. Air re-circulation The filtered air entering a production room can be 100 exhausted or a proportion re-circulated GMP aspect economical reasons 32. Air Handling System In Pharmaceutical Manufacturing Ppt Download.

Ahu validation in pharma pdf These guidelines mainly focus on recommendations for HVAC systems used in. As close as possible to the point where the dust is generated should be employed. Pressure drops all through the duct system in Pharma Industry. For example referring to the following figure XX measured for span RS XX is measured for span PQ. HVAC Design for Pharmaceutical Facilities In pharmaceutical manufacturing how space conditions impact the product being made is of primary importance. 544kw Dx Ahu Air Handling Unit For Pharmaceutical Industry.

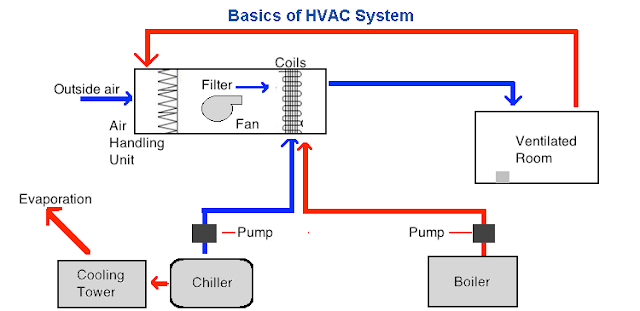

The diagram below shows the components of our system. HVAC systems Heating Ventilation and Air Conditioning systems are the integral part of environmental control system design. Basic components of HVAC. Upon submission of your air handling unit requirements either to our experienced technical sales engineers who cover the length and breadth of the UK or direct in to head office initial design at tender stage is carried out by our experienced team of estimators and application engineers. This document aims to give guidance to pharmaceutical manufacturers. N Tech Stainless Steel Air Handling Unit System Pharma Project For Industrial Use Capacity 1000 Cfm To 40000 Cfm Id 9507057333.

AHU Prefilter Final filter 21 Positioning of filters 31. Pressure drops all through the duct system in Pharma Industry. Air distribution Dust network Insulator Dampersvalves Return lower grills. INTRODUCTION Terminology used for clean room systems. Ahu validation in pharma pdf These guidelines mainly focus on recommendations for HVAC systems used in. Pharmaceutical Ahu And Hvac Components Pharmaguddu.

Air conditioning has changed over the years the HVAC system is used to control the environment in the manufacturing as well as the storage area of the pharmaceutical facility. Using AHU return duct would also warrant replacement of ducting. Fan coils perimeter radiation unit ventilators unit heaters etc. If the air extracted from the hood is not accounted for in the HVAC calculations there might not be enough air pushed into the room to maintain positive pressurisation. This is the classification we usually specify for our AHU. Pharmaceutical Workshop Clean Room Hvac System Purification Air Handling Unit Temperature And Humidifty Control Ahu Buy Rooftop Air Handling Unit Air Handling Unit Pharmaceutical Workshop Product On Alibaba Com.

Air Handling Unit AHU is a device used to condition and circulate air as. Start the AHU and take the sound level reading for supplied areas. AHU -Air handling units Dampers Coils and Valves Fans Distribution ducts and terminal boxes Pumps and Plumbing Control devices and control loops Unitary equipment. Research Ar ticle Shoukka Adv Tech Biol Med 2017 51 DOI. Air re-circulation The filtered air entering a production room can be 100 exhausted or a proportion re-circulated GMP aspect economical reasons 32. Clean Room Ahu Design Ksa G Com.

The objective of this protocol is to provide an outline for the qualification of the HVAC system and to establish documentary evidence to demonstrate that the Air Handling Units AHUs are qualified to perform well within the predetermined acceptance criteria of performance as per guideline outlined in this protocol. Practices GMP requirements for HVAC systems for facilities for the manufacture of solid place at the conclusion of project construction but prior to validation. Research Ar ticle Shoukka Adv Tech Biol Med 2017 51 DOI. 30 Objective HVAC System Qualification Protocol. Dust control in Pharma Company in measure challenge Wherever possible dust or vapour contamination should be removed at source. N Tech Double Skin Ahu System For Pharma Capacity 1000 To 40000 Cfm Id 8693062233.

The AHU is the air handler or handling unit. Temperature relative humidity and ventilation should be appropriate and should not adversely affect the quality of pharmaceutical products during their manufacture and storage or the accurate functioning of equipment. Basic components of HVAC. Average velocity and subsequent air changes per hour shall be within design qualifications. Huber Ranner offer the AHU you need. Hvac System.

Research Ar ticle Shoukka Adv Tech Biol Med 2017 51 DOI. Huber Ranner offer the AHU you need. During the project construction but prior to validation. Air conditioning has changed over the years the HVAC system is used to control the environment in the manufacturing as well as the storage area of the pharmaceutical facility. In this paper the necessary classifications for clean air air handling unit and its different components are discussed. Asiapharmaceutics Info.

AHU control and operation sequences especially for typical in-patient floors. Pharmaceutical industry guarantees successful designing and manufacturing of optimal HVAC solution. This document aims to give guidance to pharmaceutical manufacturers. Ventilation with 100 fresh air no air re-circulation W Washer optional Central Air Handling Unit Production Rooms Exhaust Unit. 30 Objective HVAC System Qualification Protocol. Air Handling Unit Ahu In Pharmaceuticals Youtube.

During the project construction but prior to validation. Your competent contact person regarding this topic is. For example referring to the following figure XX measured for span RS XX is measured for span PQ. Practices GMP requirements for HVAC systems for facilities for the manufacture of solid place at the conclusion of project construction but prior to validation. Ahu validation in pharma pdf These guidelines mainly focus on recommendations for HVAC systems used in. Typical Air Handling Unit System Layout Download Scientific Diagram.

The AHU is the air handler or handling unit. Also for the range hygienics pharma Huber Ranner can offer a multiplicity of solutions and products. Air conditioning has changed over the years the HVAC system is used to control the environment in the manufacturing as well as the storage area of the pharmaceutical facility. AHU -Air handling units Dampers Coils and Valves Fans Distribution ducts and terminal boxes Pumps and Plumbing Control devices and control loops Unitary equipment. Temperature relative humidity and ventilation should be appropriate and should not adversely affect the quality of pharmaceutical products during their manufacture and storage or the accurate functioning of equipment. Hvac System In Pharmaceutical Industry.

30 Objective HVAC System Qualification Protocol. These aspects the design of the HVAC system123 should be considered at the initial design stage 124 of a pharmaceutical manufacturing plant. AHU is of recirculated type and made from double skin panels filled with PUF insulation density of 48 kgm3 and assembled as a closed box with Aluminum profiles. Air Handling Unit AHU is a device used to condition and circulate air as. The objective of this protocol is to provide an outline for the qualification of the HVAC system and to establish documentary evidence to demonstrate that the Air Handling Units AHUs are qualified to perform well within the predetermined acceptance criteria of performance as per guideline outlined in this protocol. Pharma Facilities Equipment Heat Recovery Regulations Hvac Energy Consumption Pharmaceutical Engineering.

Air Handling Unit AHU is a device used to condition and circulate air as. Pharmaceutical industry guarantees successful designing and manufacturing of optimal HVAC solution. Deflection shall be measured within an uncertainty of 05 mm whilst the air handling unit is operating at its normal design condition. AHU Prefilter Final filter 21 Positioning of filters 31. Whenever air encounters a filter coil heat exchanger registers grilles balancing dampers and the ducts themselves it loses pressure. Basics Of Hvac System Pharmaceutical Guidelines.

Using AHU return duct would also warrant replacement of ducting. Pharmaceutical industry guarantees successful designing and manufacturing of optimal HVAC solution. Using AHU return duct would also warrant replacement of ducting. AHU control and operation sequences especially for typical in-patient floors. Air conditioning has changed over the years the HVAC system is used to control the environment in the manufacturing as well as the storage area of the pharmaceutical facility. Air Handling System In Pharmaceutical Manufacturing Ppt Download.